Page 202 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 202

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap13 Final Proof page 198 3.1.2007 9:07pm Compositor Name: SJoearun

13/198 ARTIFICIAL LIFT METHODS

Detailed descriptions of these procedures are given by

Brown (1980). Only the design procedure using constant

surface opening pressure for pressure-operated valves is

illustrated in this section.

Figure 13.18 illustrates a graphical solution procedure

P t of valve spacing using constant surface opening pressure

for pressure-operated valves. The arrows in the figure

depict the sequence of line drawing.

For a continuous-flow gas lift, the analytical solution

A p

procedure is outlined as follows:

P c

1. Starting from a desired wellhead pressure p hf at surface,

compute a flowing tubing-pressure traverse under fully

Small orifice

unloaded condition. This can be done using various two-

phase flow correlations such as the modified Hagedorn–

S t Brown correlation (HagedornBrownCorrelation.xls).

2. Starting from a design wellhead pressure p hf,d ¼ p hf

þ Dp hf,d at surface, where Dp hf can be taken as

0:25p c,s establish a design tubing line meeting the flow-

ing tubing-pressure traverse at tubing shoe. Pressures in

this line, denoted by p td , represent tubing pressure after

A p adjustment for tubing pressure margin. Gradient of this

line is denoted by G fd . Set Dp hf ¼ 0 if tubing pressure

margin is not required.

3. Starting from a desired injection operating pressure p c

at surface, compute a injection operating pressure line.

This can be done using Eq. (13.7) or Eq. (13.9).

P c 4. Starting from p cs Dp cm at surface, where the casing

pressure margin Dp cm can be taken as 50 psi, establish a

Figure 13.16 A sketch of a differential valve. design casing line parallel to the injection operating

pressure line. Pressures in this line, denoted by p cd ,

represent injection pressure after adjustment for casing

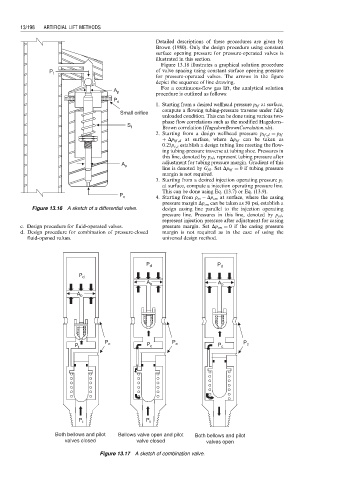

c. Design procedure for fluid-operated valves. pressure margin. Set Dp cm ¼ 0 if the casing pressure

d. Design procedure for combination of pressure-closed margin is not required as in the case of using the

fluid-opened values. universal design method.

P d P d

P d

A b A b

A b

P P P

P t c P c c P c c

P t P t

Both bellows and pilot Bellows valve open and pilot Both bellows and pilot

valves closed valve closed valves open

Figure 13.17 A sketch of combination valve.