Page 200 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 200

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap13 Final Proof page 196 3.1.2007 9:07pm Compositor Name: SJoearun

13/196 ARTIFICIAL LIFT METHODS

defined as the tubing pressure required to open the valve

q g

Gas Flow Rate under actual operating conditions. Force balance gives

1 R

P vo ¼ P d þ S t P c , (13:44)

1 R 1 R

where P c ¼ casing pressure, psig.

R

R

is called

P c is called the C.E. and

The term

P t T.E.F. for fluid valves. With other parameters given, Eq.

1 R

1 R

Tubing Pressure Throttling depth, that is, P d ¼ (1 R)P vo S t þ RP c , in valve selection.

(13.44) is used for determining required dome pressure at

range

When a fluid valve is in its open position under operat-

ing conditions, the maximum pressure under the ball (as-

sumed to be tubing pressure) required to close the valve is

called the valve closing pressure and is expressed as

P vc ¼ P d þ S t 1 Rð Þ, (13:45)

Maximum

flow rate which is identical to that for a pressure-operated valve.

The first generation of fluid valves is a differential valve.

As illustrated in Fig. 13.16, a differential valve relies on the

difference between the casing pressure and the spring

pressure effect to open and close. The opening and closing

Casing pressures are the same tubing pressure defined as

pressure

P vo ¼ P vc ¼ P c S t : (13:46)

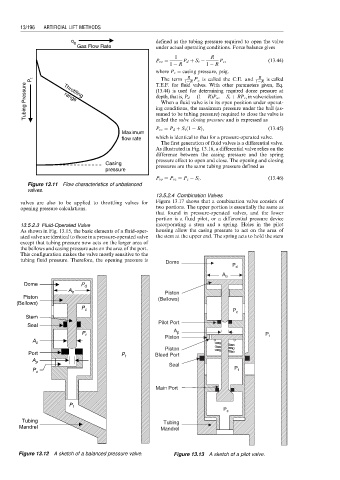

Figure 13.11 Flow characteristics of unbalanced

valves.

13.5.2.4 Combination Valves

valves are also to be applied to throttling valves for Figure 13.17 shows that a combination valve consists of

opening pressure calculations. two portions. The upper portion is essentially the same as

that found in pressure-operated valves, and the lower

portion is a fluid pilot, or a differential pressure device

13.5.2.3 Fluid-Operated Valve incorporating a stem and a spring. Holes in the pilot

As shown in Fig. 13.15, the basic elements of a fluid-oper- housing allow the casing pressure to act on the area of

ated valve are identical to those in a pressure-operated valve the stem at the upper end. The spring acts to hold the stem

except that tubing pressure now acts on the larger area of

the bellows and casing pressure acts on the area of the port.

This configuration makes the valve mostly sensitive to the

tubing fluid pressure. Therefore, the opening pressure is Dome

P d

A b

Dome P d

A b Piston

Piston (Bellows)

(Bellows)

P c

P c

Stem

Pilot Port

Seal

P t A p P t

A s Piston

Piston

Port P t Bleed Port

A p

Seal

P c P t

Main Port

P t

P c

Tubing Tubing

Mandrel Mandrel

Figure 13.12 A sketch of a balanced pressure valve. Figure 13.13 A sketch of a pilot valve.