Page 23 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 23

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap01 Final Proof page 11 4.1.2007 6:12pm Compositor Name: SJoearun

PETROLEUM PRODUCTION SYSTEM 1/11

gal compressor consists of a housing with flow passages, a most economical means of large-scale overland transpor-

rotating shaft on which the impeller is mounted, bearings, tation for crude oil, natural gas, and their products, clearly

and seals to prevent gas from escaping along the shaft. superior to rail and truck transportation over competing

Centrifugal compressors have few moving parts because routes, given large quantities to be moved on a regular

only the impeller and shaft rotate. Thus, its efficiency is basis. Transporting petroleum fluids with pipelines is

high and lubrication oil consumption and maintenance a continuous and reliable operation. Pipelines have

costs are low. Cooling water is normally unnecessary be- demonstrated an ability to adapt to a wide variety of

cause of lower compression ratio and less friction loss. environments including remote areas and hostile environ-

Compression rates of centrifugal compressors are lower ments. With very minor exceptions, largely due to local

because of the absence of positive displacement. Centrifu- peculiarities, most refineries are served by one or more

gal compressors compress gas using centrifugal force. In pipelines, because of their superior flexibility to the

this type of compressor, work is done on the gas by an alternatives.

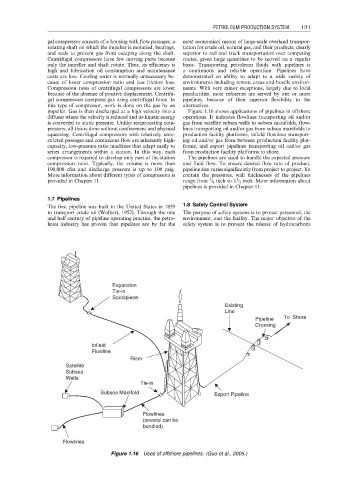

impeller. Gas is then discharged at a high velocity into a Figure 1.16 shows applications of pipelines in offshore

diffuser where the velocity is reduced and its kinetic energy operations. It indicates flowlines transporting oil and/or

is converted to static pressure. Unlike reciprocating com- gas from satellite subsea wells to subsea manifolds, flow-

pressors, all this is done without confinement and physical lines transporting oil and/or gas from subsea manifolds to

squeezing. Centrifugal compressors with relatively unre- production facility platforms, infield flowlines transport-

stricted passages and continuous flow are inherently high- ing oil and/or gas from between production facility plat-

capacity, low-pressure ratio machines that adapt easily to forms, and export pipelines transporting oil and/or gas

series arrangements within a station. In this way, each from production facility platforms to shore.

compressor is required to develop only part of the station The pipelines are sized to handle the expected pressure

compression ratio. Typically, the volume is more than and fluid flow. To ensure desired flow rate of product,

100,000 cfm and discharge pressure is up to 100 psig. pipeline size varies significantly from project to project. To

More information about different types of compressors is contain the pressures, wall thicknesses of the pipelines

3

1

provided in Chapter 11. range from ⁄ 8 inch to 1 ⁄ 2 inch. More information about

pipelines is provided in Chapter 11.

1.7 Pipelines

1.8 Safety Control System

The first pipeline was built in the United States in 1859

to transport crude oil (Wolbert, 1952). Through the one The purpose of safety systems is to protect personnel, the

and half century of pipeline operating practice, the petro- environment, and the facility. The major objective of the

leum industry has proven that pipelines are by far the safety system is to prevent the release of hydrocarbons

Expansion

Tie-in

Spoolpiece

Existing

Line

Pipeline To Shore

Crossing

Infield

Flowline

Riser

Satellite

Subsea

Wells

Tie-in

Subsea Manifold Export Pipeline

Flowlines

(several can be

bundled)

Flowlines

Figure 1.16 Uses of offshore pipelines. (Guo et al., 2005.)