Page 22 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 22

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap01 Final Proof page 10 4.1.2007 6:12pm Compositor Name: SJoearun

1/10 PETROLEUM PRODUCTION ENGINEERING FUNDAMENTALS

Discharge Discharge

P 2 P 2

Piston

Piston Rod d L

d r

L s

P 1 P 1

Suction Suction

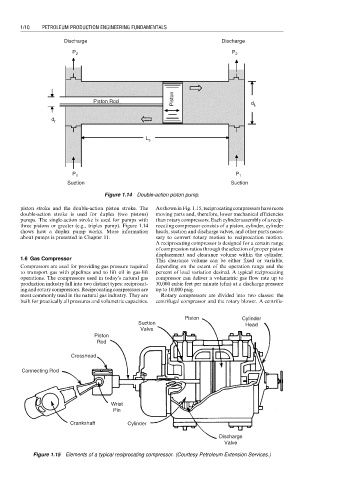

Figure 1.14 Double-action piston pump.

piston stroke and the double-action piston stroke. The Asshown in Fig. 1.15, reciprocating compressors have more

double-action stroke is used for duplex (two pistons) moving parts and, therefore, lower mechanical efficiencies

pumps. The single-action stroke is used for pumps with than rotary compressors. Each cylinder assembly of a recip-

three pistons or greater (e.g., triplex pump). Figure 1.14 rocating compressor consists of a piston, cylinder, cylinder

shows how a duplex pump works. More information heads, suction and discharge valves, and other parts neces-

about pumps is presented in Chapter 11. sary to convert rotary motion to reciprocation motion.

A reciprocating compressor is designed for a certain range

of compression ratios through the selection of proper piston

displacement and clearance volume within the cylinder.

1.6 Gas Compressor This clearance volume can be either fixed or variable,

Compressors are used for providing gas pressure required depending on the extent of the operation range and the

to transport gas with pipelines and to lift oil in gas-lift percent of load variation desired. A typical reciprocating

operations. The compressors used in today’s natural gas compressor can deliver a volumetric gas flow rate up to

production industry fall into two distinct types: reciprocat- 30,000 cubic feet per minute (cfm) at a discharge pressure

ing and rotary compressors. Reciprocating compressors are up to 10,000 psig.

most commonly used in the natural gas industry. They are Rotary compressors are divided into two classes: the

built for practically all pressures and volumetric capacities. centrifugal compressor and the rotary blower. A centrifu-

Piston Cylinder

Suction Head

Valve

Piston

Rod

Crosshead

Connecting Rod

Wrist

Pin

Crankshaft Cylinder

Discharge

Valve

Figure 1.15 Elements of a typical reciprocating compressor. (Courtesy Petroleum Extension Services.)