Page 18 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 18

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap01 Final Proof page 6 4.1.2007 6:12pm Compositor Name: SJoearun

1/6 PETROLEUM PRODUCTION ENGINEERING FUNDAMENTALS

The ‘‘wellhead’’ is defined as the surface equipment set

below the master valve. As we can see in Fig. 1.7, it

includes casing heads and a tubing head. The casing head

(lowermost) is threaded onto the surface casing. This can

also be a flanged or studded connection. A ‘‘casing head’’

is a mechanical assembly used for hanging a casing string

(Fig. 1.8). Depending on casing programs in well drilling,

several casing heads can be installed during well construc-

tion. The casing head has a bowl that supports the casing

hanger. This casing hanger is threaded onto the top of the

production casing (or uses friction grips to hold the cas-

ing). As in the case of the production tubing, the produc-

tion casing is landed in tension so that the casing hanger

actually supports the production casing (down to the

freeze point). In a similar manner, the intermediate cas-

ing(s) are supported by their respective casing hangers

(and bowls). All of these casing head arrangements are

supported by the surface casing, which is in compression

and cemented to the surface. A well completed with three

Gas Cap casing strings has two casing heads. The uppermost casing

head supports the production casing. The lowermost cas-

ing head sits on the surface casing (threaded to the top of

the surface casing).

Most flowing wells are produced through a string of

tubing run inside the production casing string. At the

Oil surface, the tubing is supported by the tubing head (i.e.,

the tubing head is used for hanging tubing string on the

production casing head [Fig. 1.9]). The tubing head sup-

ports the tubing string at the surface (this tubing is landed

on the tubing head so that it is in tension all the way down

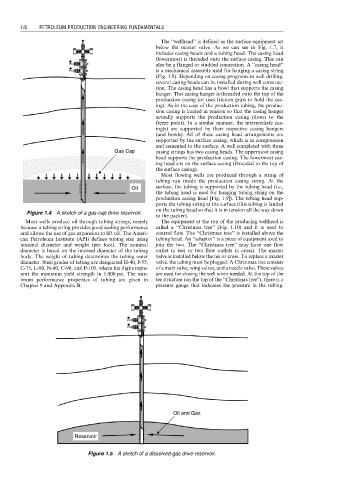

Figure 1.4 A sketch of a gas-cap drive reservoir.

to the packer).

Most wells produce oil through tubing strings, mainly The equipment at the top of the producing wellhead is

because a tubing string provides good sealing performance called a ‘‘Christmas tree’’ (Fig. 1.10) and it is used to

and allows the use of gas expansion to lift oil. The Ameri- control flow. The ‘‘Christmas tree’’ is installed above the

can Petroleum Institute (API) defines tubing size using tubing head. An ‘‘adaptor’’ is a piece of equipment used to

nominal diameter and weight (per foot). The nominal join the two. The ‘‘Christmas tree’’ may have one flow

diameter is based on the internal diameter of the tubing outlet (a tee) or two flow outlets (a cross). The master

body. The weight of tubing determines the tubing outer valve is installed below the tee or cross. To replace a master

diameter. Steel grades of tubing are designated H-40, J-55, valve, the tubing must be plugged. A Christmas tree consists

C-75, L-80, N-80, C-90, and P-105, where the digits repre- of a main valve, wing valves, and a needle valve. These valves

sent the minimum yield strength in 1,000 psi. The min- are used for closing the well when needed. At the top of the

imum performance properties of tubing are given in tee structure (on the top of the ‘‘Christmas tree’’), there is a

Chapter 9 and Appendix B. pressure gauge that indicates the pressure in the tubing.

Oil and Gas

Reservoir

Figure 1.5 A sketch of a dissolved-gas drive reservoir.