Page 20 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 20

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap01 Final Proof page 8 4.1.2007 6:12pm Compositor Name: SJoearun

1/8 PETROLEUM PRODUCTION ENGINEERING FUNDAMENTALS

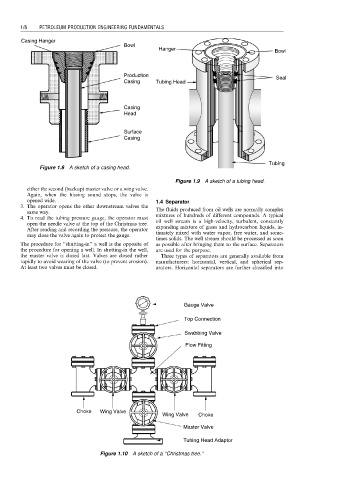

Casing Hanger

Bowl

Hanger Bowl

Production Seal

Casing Tubing Head

Casing

Head

Surface

Casing

Tubing

Figure 1.8 A sketch of a casing head.

Figure 1.9 A sketch of a tubing head.

either the second (backup) master valve or a wing valve.

Again, when the hissing sound stops, the valve is

opened wide. 1.4 Separator

3. The operator opens the other downstream valves the

same way. The fluids produced from oil wells are normally complex

4. To read the tubing pressure gauge, the operator must mixtures of hundreds of different compounds. A typical

open the needle valve at the top of the Christmas tree. oil well stream is a high-velocity, turbulent, constantly

After reading and recording the pressure, the operator expanding mixture of gases and hydrocarbon liquids, in-

may close the valve again to protect the gauge. timately mixed with water vapor, free water, and some-

times solids. The well stream should be processed as soon

The procedure for ‘‘shutting-in’’ a well is the opposite of as possible after bringing them to the surface. Separators

the procedure for opening a well. In shutting-in the well, are used for the purpose.

the master valve is closed last. Valves are closed rather Three types of separators are generally available from

rapidly to avoid wearing of the valve (to prevent erosion). manufacturers: horizontal, vertical, and spherical sep-

At least two valves must be closed. arators. Horizontal separators are further classified into

Gauge Valve

Top Connection

Swabbing Valve

Flow Fitting

Choke Wing Valve

Wing Valve Choke

Master Valve

Tubing Head Adaptor

Figure 1.10 A sketch of a ‘‘Christmas tree.’’