Page 19 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 19

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap01 Final Proof page 7 4.1.2007 6:12pm Compositor Name: SJoearun

PETROLEUM PRODUCTION SYSTEM 1/7

in the line. The back-pressure (caused by the chokes or

other restrictions in the flowline) increases the bottom-

hole flowing pressure. Increasing the bottom-hole flowing

pressure decreases the pressure drop from the reservoir to

the wellbore (pressure drawdown). Thus, increasing the

back-pressure in the wellbore decreases the flow rate

Wellhead from the reservoir.

In some wells, chokes are installed in the lower section

of tubing strings. This choke arrangement reduces well-

head pressure and enhances oil production rate as a result

of gas expansion in the tubing string. For gas wells, use of

Surface Casing down-hole chokes minimizes the gas hydrate problem in

Intermediate Casing the well stream. A major disadvantage of using down-hole

chokes is that replacing a choke is costly.

Cement

Production Casing Certain procedures must be followed to open or close a

Annulus well. Before opening, check all the surface equipment such

as safety valves, fittings, and so on. The burner of a line

heater must be lit before the well is opened. This is neces-

Wellbore Tubing sary because the pressure drop across a choke cools the

fluid and may cause gas hydrates or paraffin to deposit

out. A gas burner keeps the involved fluid (usually water)

Bottom-hole Choke hot. Fluid from the well is carried through a coil of piping.

The choke is installed in the heater. Well fluid is heated

Packer both before and after it flows through the choke. The

upstream heating helps melt any solids that may be present

Casing Perforation in the producing fluid. The downstream heating prevents

Reservoir hydrates and paraffins from forming at the choke.

Oil Reservoir

Surface vessels should be open and clear before the well

is allowed to flow. All valves that are in the master valve

Figure 1.6 A sketch of a typical flowing oil well.

and other downstream valves are closed. Then follow the

following procedure to open a well:

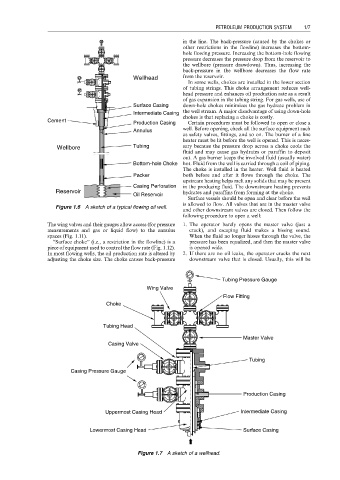

The wing valves and their gauges allow access (for pressure 1. The operator barely opens the master valve (just a

measurements and gas or liquid flow) to the annulus crack), and escaping fluid makes a hissing sound.

spaces (Fig. 1.11). When the fluid no longer hisses through the valve, the

‘‘Surface choke’’ (i.e., a restriction in the flowline) is a pressure has been equalized, and then the master valve

piece of equipment used to control the flow rate (Fig. 1.12). is opened wide.

In most flowing wells, the oil production rate is altered by 2. If there are no oil leaks, the operator cracks the next

adjusting the choke size. The choke causes back-pressure downstream valve that is closed. Usually, this will be

Tubing Pressure Gauge

Wing Valve

Flow Fitting

Choke

Tubing Head

Master Valve

Casing Valve

Tubing

Casing Pressure Gauge

Production Casing

Uppermost Casing Head Intermediate Casing

Lowermost Casing Head Surface Casing

Figure 1.7 A sketch of a wellhead.