Page 21 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 21

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap01 Final Proof page 9 4.1.2007 6:12pm Compositor Name: SJoearun

PETROLEUM PRODUCTION SYSTEM 1/9

Handwheel

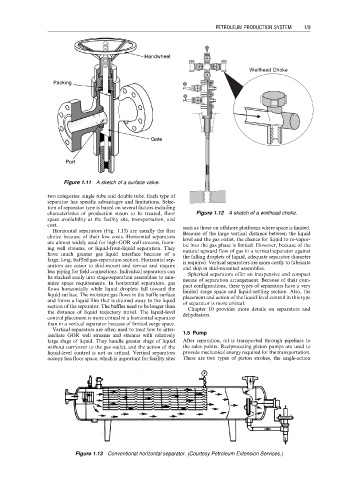

Wellhead Choke

Packing

Gate

Port

Figure 1.11 A sketch of a surface valve.

two categories: single tube and double tube. Each type of

separator has specific advantages and limitations. Selec-

tion of separator type is based on several factors including

characteristics of production steam to be treated, floor Figure 1.12 A sketch of a wellhead choke.

space availability at the facility site, transportation, and

cost. such as those on offshore platforms where space is limited.

Horizontal separators (Fig. 1.13) are usually the first Because of the large vertical distance between the liquid

choice because of their low costs. Horizontal separators level and the gas outlet, the chance for liquid to re-vapor-

are almost widely used for high-GOR well streams, foam- ize into the gas phase is limited. However, because of the

ing well streams, or liquid-from-liquid separation. They

have much greater gas–liquid interface because of a natural upward flow of gas in a vertical separator against

large, long, baffled gas-separation section. Horizontal sep- the falling droplets of liquid, adequate separator diameter

arators are easier to skid-mount and service and require is required. Vertical separators are more costly to fabricate

less piping for field connections. Individual separators can and ship in skid-mounted assemblies.

be stacked easily into stage-separation assemblies to min- Spherical separators offer an inexpensive and compact

imize space requirements. In horizontal separators, gas means of separation arrangement. Because of their com-

pact configurations, these types of separators have a very

flows horizontally while liquid droplets fall toward the limited surge space and liquid-settling section. Also, the

liquid surface. The moisture gas flows in the baffle surface placement and action of the liquid-level control in this type

and forms a liquid film that is drained away to the liquid of separator is more critical.

section of the separator. The baffles need to be longer than Chapter 10 provides more details on separators and

the distance of liquid trajectory travel. The liquid-level dehydrators.

control placement is more critical in a horizontal separator

than in a vertical separator because of limited surge space.

Vertical separators are often used to treat low to inter-

mediate GOR well streams and streams with relatively 1.5 Pump

large slugs of liquid. They handle greater slugs of liquid After separation, oil is transported through pipelines to

without carryover to the gas outlet, and the action of the the sales points. Reciprocating piston pumps are used to

liquid-level control is not as critical. Vertical separators provide mechanical energy required for the transportation.

occupy less floor space, which is important for facility sites There are two types of piston strokes, the single-action

Figure 1.13 Conventional horizontal separator. (Courtesy Petroleum Extension Services.)