Page 234 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 234

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap15 Final Proof page 232 22.12.2006 6:14pm

15/232 PRODUCTION ENHANCEMENT

1,000

Delta P and P-Derivative (psi) 100 Radial Flow

Begging

of Pseudo

Flow

Vertical Radial

Flow Pseudo Linear

10

0.001 0.01 0.1 1 10 100 1,000

Elapsed Time (hours)

Figure 15.4 Log-log diagnostic plot of test data.

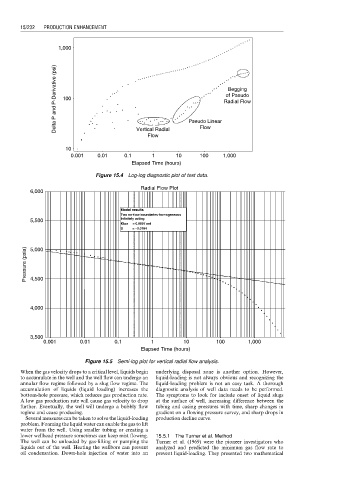

Radial Flow Plot

6,000

Model results

Two no-flow boundaries-homogeneous

5,500 Infinitely acting

Kbar = 0.9997 md

S = −0.0164

Pressure (psia) 5,000

4,500

4,000

3,500

0.001 0.01 0.1 1 10 100 1,000

Elapsed Time (hours)

Figure 15.5 Semi-log plot for vertical radial flow analysis.

When the gas velocity drops to a critical level, liquids begin underlying disposal zone is another option. However,

to accumulate in the well and the well flow can undergo an liquid-loading is not always obvious and recognizing the

annular flow regime followed by a slug flow regime. The liquid-loading problem is not an easy task. A thorough

accumulation of liquids (liquid loading) increases the diagnostic analysis of well data needs to be performed.

bottom-hole pressure, which reduces gas production rate. The symptoms to look for include onset of liquid slugs

A low gas production rate will cause gas velocity to drop at the surface of well, increasing difference between the

further. Eventually, the well will undergo a bubbly flow tubing and casing pressures with time, sharp changes in

regime and cease producing. gradient on a flowing pressure survey, and sharp drops in

Several measures can be taken to solve the liquid-loading production decline curve.

problem. Foaming the liquid water can enable the gas to lift

water from the well. Using smaller tubing or creating a

lower wellhead pressure sometimes can keep mist flowing. 15.5.1 The Turner et al. Method

The well can be unloaded by gas-lifting or pumping the Turner et al. (1969) were the pioneer investigators who

liquids out of the well. Heating the wellbore can prevent analyzed and predicted the minimum gas flow rate to

oil condensation. Down-hole injection of water into an prevent liquid-loading. They presented two mathematical