Page 253 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 253

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap17 Final Proof page 252 3.1.2007 9:19pm Compositor Name: SJoearun

17/252 PRODUCTION ENHANCEMENT

17.1 Introduction reduce the injection rate requirement, a low leaf-off frac-

turing fluid is essential. Also, to prop the fracture, the sand/

Hydraulic fracturing is a well-stimulation technique that is

most suitable to wells in low- and moderate-permeability proppant should have a compressive strength that is high

reservoirs that do not provide commercial production enough to resist the stress from the formation.

rates even though formation damages are removed by This chapter concisely describes hydraulic fracturing

acidizing treatments. treatments. For detailed information on this subject, see

Hydraulic fracturing jobs are carried out at well sites Economides and Nolte (2000). This chapter focuses on the

using heavy equipment including truck-mounted pumps, following topics:

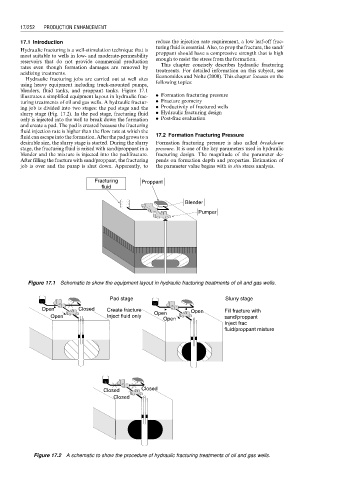

blenders, fluid tanks, and proppant tanks. Figure 17.1

illustrates a simplified equipment layout in hydraulic frac- . Formation fracturing pressure

turing treatments of oil and gas wells. A hydraulic fractur- . Fracture geometry

ing job is divided into two stages: the pad stage and the . Productivity of fractured wells

slurry stage (Fig. 17.2). In the pad stage, fracturing fluid . Hydraulic fracturing design

only is injected into the well to break down the formation . Post-frac evaluation

and create a pad. The pad is created because the fracturing

fluid injection rate is higher than the flow rate at which the

fluid can escape into the formation. After the pad grows to a 17.2 Formation Fracturing Pressure

desirable size, the slurry stage is started. During the slurry Formation fracturing pressure is also called breakdown

stage, the fracturing fluid is mixed with sand/proppant in a pressure. It is one of the key parameters used in hydraulic

blender and the mixture is injected into the pad/fracture. fracturing design. The magnitude of the parameter de-

After filling the fracture with sand/proppant, the fracturing pends on formation depth and properties. Estimation of

job is over and the pump is shut down. Apparently, to the parameter value begins with in situ stress analysis.

Fracturing Proppant

fluid

Blender

Pumper

Figure 17.1 Schematic to show the equipment layout in hydraulic fracturing treatments of oil and gas wells.

Pad stage Slurry stage

Open Closed Create fracture Open Fill fracture with

Open Inject fluid only Open sand/proppant

Open

Inject frac

fluid/proppant mixture

Closed Closed

Closed

Figure 17.2 A schematic to show the procedure of hydraulic fracturing treatments of oil and gas wells.