Page 254 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 254

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap17 Final Proof page 253 3.1.2007 9:19pm Compositor Name: SJoearun

HYDRAULIC FRACTURING 17/253

Gas

Oil

Water

p tf

H

p wt

p

p e

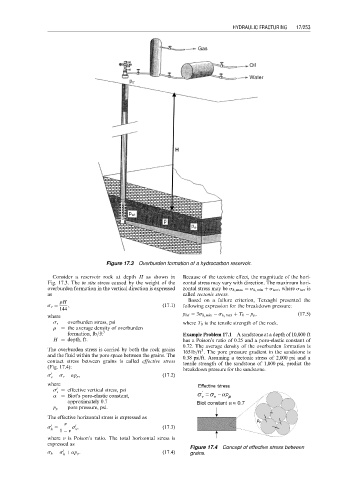

Figure 17.3 Overburden formation of a hydrocarbon reservoir.

Consider a reservoir rock at depth H as shown in Because of the tectonic effect, the magnitude of the hori-

Fig. 17.3. The in situ stress caused by the weight of the zontal stress may vary with direction. The maximum hori-

overburden formation in the vertical direction is expressed zontal stress may be s h, max ¼ s h, min þ s tect , where s tect is

as called tectonic stress.

rH Based on a failure criterion, Terzaghi presented the

s v ¼ , (17:1) following expression for the breakdown pressure:

144

p bd ¼ 3s h, min s h, max þ T 0 p p , (17:5)

where

s v ¼ overburden stress, psi where T 0 is the tensile strength of the rock.

r ¼ the average density of overburden

formation, lb=ft 3 Example Problem 17.1 A sandstone at a depth of 10,000 ft

H ¼ depth, ft. has a Poison’s ratio of 0.25 and a poro-elastic constant of

0.72. The average density of the overburden formation is

The overburden stress is carried by both the rock grains 165 lb=ft . The pore pressure gradient in the sandstone is

3

and the fluid within the pore space between the grains. The 0.38 psi/ft. Assuming a tectonic stress of 2,000 psi and a

contact stress between grains is called effective stress tensile strength of the sandstone of 1,000 psi, predict the

(Fig. 17.4):

breakdown pressure for the sandstone.

0

s ¼ s v ap p , (17:2)

v

where

0

s ¼ effective vertical stress, psi

v

a ¼ Biot’s poro-elastic constant,

approximately 0.7

p p ¼ pore pressure, psi.

The effective horizontal stress is expressed as

n

0

0

s ¼ s , (17:3)

h

1 n v

where n is Poison’s ratio. The total horizontal stress is

expressed as

Figure 17.4 Concept of effective stress between

0

s h ¼ s þ ap p : (17:4) grains.

h