Page 255 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 255

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap17 Final Proof page 254 3.1.2007 9:19pm Compositor Name: SJoearun

17/254 PRODUCTION ENHANCEMENT

1

ð

Solution mq i 1 nÞR 4

w w ¼ 2:56 , (17:6)

Overburden stress: E

rH (165)(10,000) where

s v ¼ ¼ ¼ 11,500 psi w w ¼ fracture width at wellbore, in.

144 144

m ¼ fluid viscosity, cp

Pore pressure:

q i ¼ pumping rate, bpm

p p ¼ (0:38)(10,000) ¼ 3,800 psi R ¼ the radius of the fracture, ft

E ¼ Young’s modulus, psi.

The effective vertical stress:

0

s ¼ s v ap p ¼ 11,500 (0:72)(3,800) ¼ 8,800 psi Assuming the fracture width drops linearly in the radial

v

direction, the average fracture width may be expressed as

The effective horizontal stress: mq i 1 nÞR 1 4

ð

0

0

s ¼ n s ¼ 0:25 ð 8,800Þ ¼ 2,900 psi w ¼ 0:85 E : (17:7)

h

1 n v 1 0:25

The minimum horizontal stress:

17.3.2 The KGD Model

0

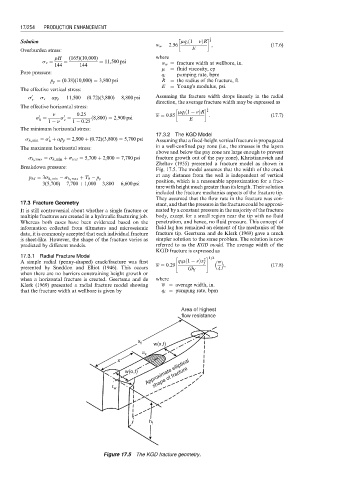

s h, min ¼ s þ ap p ¼ 2,900 þ (0:72)(3,800) ¼ 5,700 psi Assuming that a fixed-height vertical fracture is propagated

h

The maximum horizontal stress: in a well-confined pay zone (i.e., the stresses in the layers

above and below the pay zone are large enough to prevent

s h, max ¼ s h, min þ s tect ¼ 5,700 þ 2,000 ¼ 7,700 psi fracture growth out of the pay zone), Khristianovich and

Zheltov (1955) presented a fracture model as shown in

Breakdown pressure:

Fig. 17.5. The model assumes that the width of the crack

at any distance from the well is independent of vertical

p bd ¼ 3s h, min s h, max þ T 0 p p position, which is a reasonable approximation for a frac-

¼ 3(5,700) 7,700 þ 1,000 3,800 ¼ 6,600 psi

ture with height much greater than its length. Their solution

included the fracture mechanics aspects of the fracture tip.

They assumed that the flow rate in the fracture was con-

17.3 Fracture Geometry stant, and that the pressure in the fracture could be approxi-

It is still controversial about whether a single fracture or mated by a constant pressure in the majority of the fracture

multiple fractures are created in a hydraulic fracturing job. body, except for a small region near the tip with no fluid

Whereas both cases have been evidenced based on the penetration, and hence, no fluid pressure. This concept of

information collected from tiltmeters and microseismic fluid lag has remained an element of the mechanics of the

data, it is commonly accepted that each individual fracture fracture tip. Geertsma and de Klerk (1969) gave a much

is sheet-like. However, the shape of the fracture varies as simpler solution to the same problem. The solution is now

predicted by different models. referred to as the KGD model. The average width of the

KGD fracture is expressed as

17.3.1 Radial Fracture Model " # 1=4

ð

p

A simple radial (penny-shaped) crack/fracture was first q i m 1 nÞx 2 f

w ¼ 0:29 , (17:8)

presented by Sneddon and Elliot (1946). This occurs 4

Gh f

when there are no barriers constraining height growth or

when a horizontal fracture is created. Geertsma and de where

Klerk (1969) presented a radial fracture model showing w ¼ average width, in.

that the fracture width at wellbore is given by q i ¼ pumping rate, bpm

Area of highest

flow resistance

x f w(x,t)

u x

x

shape of fracture

w(o,t) Approximate elliptical

r w

h f

Figure 17.5 The KGD fracture geometry.