Page 260 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 260

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap17 Final Proof page 259 3.1.2007 9:19pm Compositor Name: SJoearun

HYDRAULIC FRACTURING 17/259

17.5.2 Selection of Proppant s ¼ n rH

0

Proppant must be selected on the basis of in situ stress h 1 n 144 ap p

conditions. Major concerns are compressive strength and 0:25 (165)(10,000)

the effect of stress on proppant permeability. For a vertical ¼ (0:7)(2500) ¼ 3,236 psi

fracture, the compressive strength of the proppant should 1 0:25 144

be greater than the effective horizontal stress. In general, Therefore, the minimum required proppant compressive

bigger proppant yields better permeability, but proppant strength is 3,236 psi. Figure 17.9 indicates that the pack of

size must be checked against proppant admittance criteria the intermediate-strength proppants will have a perme-

through the perforations and inside the fracture. Figure ability of about k f ¼ 500 darcies.

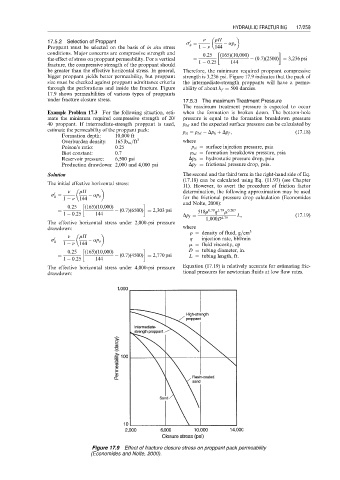

17.9 shows permeabilities of various types of proppants

under fracture closure stress. 17.5.3 The maximum Treatment Pressure

The maximum treatment pressure is expected to occur

Example Problem 17.3 For the following situation, esti- when the formation is broken down. The bottom-hole

mate the minimum required compressive strength of 20/ pressure is equal to the formation breakdown pressure

40 proppant. If intermediate-strength proppant is used, p bd and the expected surface pressure can be calculated by

estimate the permeability of the proppant pack: p si ¼ p bd Dp h þ Dp f , (17:18)

Formation depth: 10,000 ft

Overburden density: 165 lb m =ft 3 where

Poison’s ratio: 0.25 p si ¼ surface injection pressure, psia

Biot constant: 0.7 p bd ¼ formation breakdown pressure, psia

Reservoir pressure: 6,500 psi Dp h ¼ hydrostatic pressure drop, psia

Production drawdown: 2,000 and 4,000 psi Dp f ¼ frictional pressure drop, psia.

Solution The second and the third term in the right-hand side of Eq.

(17.18) can be calculated using Eq. (11.93) (see Chapter

The initial effective horizontal stress:

11). However, to avert the procedure of friction factor

n rH determination, the following approximation may be used

0

s ¼ ap p

h

1 n 144 for the frictional pressure drop calculation (Economides

and Nolte, 2000):

0:25 (165)(10,000)

¼ (0:7)(6500) ¼ 2,303 psi 518r 0:79 1:79 m 0:207

q

1 0:25 144 Dp f ¼ L, (17:19)

1,000D 4:79

The effective horizontal stress under 2,000-psi pressure

drawdown: where

r ¼ density of fluid, g=cm 3

n rH

0

s ¼ 1 n 144 ap p q ¼ injection rate, bbl/min

h

m ¼ fluid viscosity, cp

0:25 (165)(10,000) D ¼ tubing diameter, in.

¼ (0:7)(4500) ¼ 2,770 psi L ¼ tubing length, ft.

1 0:25 144

The effective horizontal stress under 4,000-psi pressure Equation (17.19) is relatively accurate for estimating fric-

drawdown: tional pressures for newtonian fluids at low flow rates.

Figure 17.9 Effect of fracture closure stress on proppant pack permeability

(Economides and Nolte, 2000).