Page 56 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 56

Guo, Boyun / Petroleum Production Engineering, A Computer-Assisted Approach 0750682701_chap04 Final Proof page 47 22.12.2006 6:07pm

WELLBORE PERFORMANCE 4/47

0.1 Relative Roughness

0

0.09

0.000001

0.000005

Turbulent Flow

0.08

0.00001

0.00005

0.07

0.0001

0.0002

0.06

0.0004

Friction Factor 0.05 0.0006

0.001

0.04 0.002

0.004

0.006

0.03

Laminar 0.01

Flow

0.015

0.02

0.02

0.03

0.01

0.04

0.05

0

1.E+02 1.E+03 1.E+04 1.E+05 1.E+06 1.E+07 1.E+08

Reynolds Number

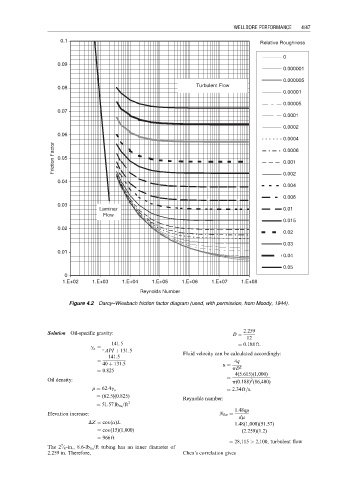

Figure 4.2 Darcy–Wiesbach friction factor diagram (used, with permission, from Moody, 1944).

2:259

Solution Oil-specific gravity: D ¼

12

141:5 ¼ 0:188 ft:

g o ¼

API þ 131:5

141:5 Fluid velocity can be calculated accordingly:

¼ 4q

40 þ 131:5 u ¼

¼ 0:825 pD 2

4(5:615)(1,000)

¼

Oil density: p(0:188) (86,400)

2

¼ 2:34 ft=s:

r ¼ 62:4g o

¼ (62:5)(0:825)

Reynolds number:

¼ 51:57 lb m =ft 3

1:48qr

Elevation increase: N Re ¼

dm

DZ ¼ cos (a)L 1:48(1,000)(51:57)

¼

¼ cos (15)(1,000) (2:259)(1:2)

¼ 966 ft

¼ 28,115 > 2,100, turbulent flow

7

The 2 ⁄ 8 -in., 8:6-lb m =ft tubing has an inner diameter of

2.259 in. Therefore, Chen’s correlation gives