Page 145 -

P. 145

7.10 CHAPTER SEVEN

t "~:,0*o *

ij "~..r" ,T ,* ¢,. Of Chin & Tee Roi|e -6 '

f..~ ~..- .ODenir~ in Floor For _~1~| Effluent Weirs

I ',] Chain S Tee Rails ,,,

1

ii ° ~o

ptan Vl,~w

Odve Unit ~ "~ nk h

~ ~ Tank lee th ~-

| ! - Chain Tiqhmner Effluent Weirs I

~ ~ . ~ n . I-" . . . . . ,, I. i i i ,~

I I'~" 1 ,~, ..... ,. U

ul l:'.~l I i II I ~. ' ,° i L _L_.~.'.') /

- t E ~ I ~ . ~ ............... ,-"~: . . . . . . . . . . . . .

t - ~ /Idin. Slope 1/16 P~ Fool "25" Tee Rails Corner $¢retded Wlth Radius

Min. Slope 45"

\,'., ~;,, :/ Sect;on A-A

~. :1 C-'OSl Collector Min. Wid1'h 3%0"

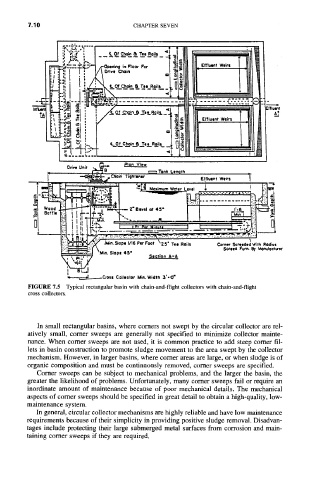

FIGURE 7.5 Typical rectangular basin with chain-and-flight collectors with chain-and-flight

cross collectors.

In small rectangular basins, where comers not swept by the circular collector are rel-

atively small, comer sweeps are generally not specified to minimize collector mainte-

nance. When corner sweeps are not used, it is common practice to add steep comer fil-

lets in basin construction to promote sludge movement to the area swept by the collector

mechanism. However, in larger basins, where comer areas are large, or when sludge is of

organic composition and must be continuously removed, comer sweeps are specified.

Comer sweeps can be subject to mechanical problems, and the larger the basin, the

greater the likelihood of problems. Unfortunately, many comer sweeps fail or require an

inordinate amount of maintenance because of poor mechanical details. The mechanical

aspects of comer sweeps should be specified in great detail to obtain a high-quality, low-

maintenance system.

In general, circular collector mechanisms are highly reliable and have low maintenance

requirements because of their simplicity in providing positive sludge removal. Disadvan-

tages include protecting their large submerged metal surfaces from corrosion and main-

taining comer sweeps if they are required.