Page 147 -

P. 147

7.12 CHAPTER SEVEN

DRIVE SPROCKET WITH

CROSS SECTION

LONGITUDINAL SECTION

HELICAL-SCREW-TYPE CROSS COLLECTOR

PIVOl

CROSS SECTION

CHAIN-AND-FLIGHT-TYPE CROSS COLLECTOR

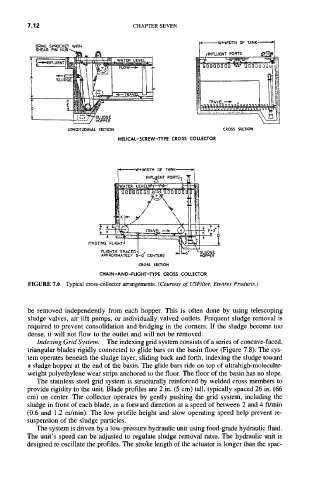

FIGURE 7.6 Typical cross-collector arrangements. (Courtesy of USFilter, Envirex Products.)

be removed independently from each hopper. This is often done by using telescoping

sludge valves, air lift pumps, or individually valved outlets. Frequent sludge removal is

required to prevent consolidation and bridging in the comers. If the sludge become too

dense, it will not flow to the outlet and will not be removed.

Indexing Grid System. The indexing grid system consists of a series of concave-faced,

triangular blades rigidly connected to glide bars on the basin floor (Figure 7.8). The sys-

tem operates beneath the sludge layer, sliding back and forth, indexing the sludge toward

a sludge hopper at the end of the basin. The glide bars ride on top of ultrahigh-molecular-

weight polyethylene wear strips anchored to the floor. The floor of the basin has no slope.

The stainless steel grid system is structurally reinforced by welded cross members to

provide rigidity to the unit. Blade profiles are 2 in. (5 cm) tall, typically spaced 26 in. (66

cm) on center. The collector operates by gently pushing the grid system, including the

sludge in front of each blade, in a forward direction at a speed of between 2 and 4 ft/min

(0.6 and 1.2 m/min). The low profile height and slow operating speed help prevent re-

suspension of the sludge particles.

The system is driven by a low-pressure hydraulic unit using food-grade hydraulic fluid.

The unit's speed can be adjusted to regulate sludge removal rates. The hydraulic unit is

designed to oscillate the profiles. The stroke length of the actuator is longer than the spac-