Page 147 - A Comprehensive Guide to Solar Energy Systems

P. 147

146 A COmPREHEnSIVE GuIdE TO SOlAR EnERGy SySTEmS

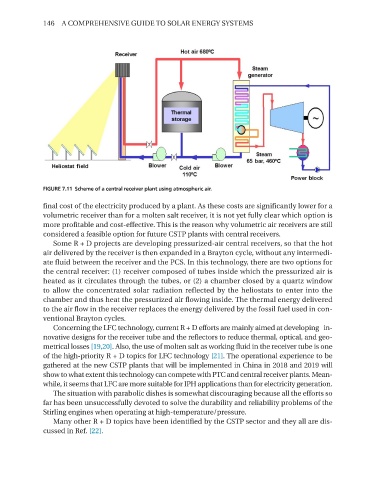

FIGURE 7.11 Scheme of a central receiver plant using atmospheric air.

final cost of the electricity produced by a plant. As these costs are significantly lower for a

volumetric receiver than for a molten salt receiver, it is not yet fully clear which option is

more profitable and cost-effective. This is the reason why volumetric air receivers are still

considered a feasible option for future CSTP plants with central receivers.

Some R + d projects are developing pressurized-air central receivers, so that the hot

air delivered by the receiver is then expanded in a Brayton cycle, without any intermedi-

ate fluid between the receiver and the PCS. In this technology, there are two options for

the central receiver: (1) receiver composed of tubes inside which the pressurized air is

heated as it circulates through the tubes, or (2) a chamber closed by a quartz window

to allow the concentrated solar radiation reflected by the heliostats to enter into the

chamber and thus heat the pressurized air flowing inside. The thermal energy delivered

to the air flow in the receiver replaces the energy delivered by the fossil fuel used in con-

ventional Brayton cycles.

Concerning the lFC technology, current R + d efforts are mainly aimed at developing in-

novative designs for the receiver tube and the reflectors to reduce thermal, optical, and geo-

metrical losses [19,20]. Also, the use of molten salt as working fluid in the receiver tube is one

of the high-priority R + d topics for lFC technology [21]. The operational experience to be

gathered at the new CSTP plants that will be implemented in China in 2018 and 2019 will

show to what extent this technology can compete with PTC and central receiver plants. mean-

while, it seems that lFC are more suitable for IPH applications than for electricity generation.

The situation with parabolic dishes is somewhat discouraging because all the efforts so

far has been unsuccessfully devoted to solve the durability and reliability problems of the

Stirling engines when operating at high-temperature/pressure.

many other R + d topics have been identified by the CSTP sector and they all are dis-

cussed in Ref. [22].