Page 360 - A Comprehensive Guide to Solar Energy Systems

P. 360

Chapter 18 • Thin Film Photovoltaics 365

The as deposited CdTe/Cds solar cells always exhibit poor photovoltaic properties

and thus require a special CdCl 2 annealing treatment that improves the cell efficiency

considerably (by a factor of 3–5) due to favorable recrystallization of the absorber leading

to a robust interface formation.

2

First solar (usA) leads the production of CdTe modules (2.47 m ) delivering on average

17% efficiencies with a current annual production capacity reaching around 3 GW, which

is due to be scaled up to 7 GW by 2019. due to the ease and speed of its production CdTe

offers the least payback time <1 year among all competing technologies including c-Si,

thus making it one of the fastest growing technologies.

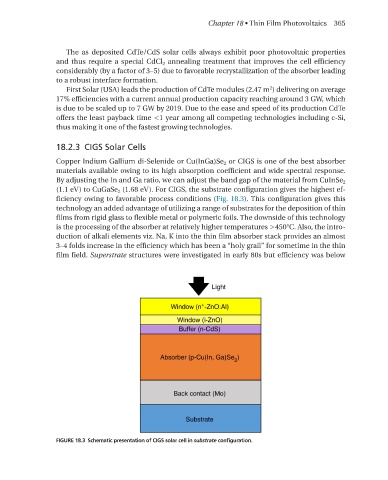

18.2.3 CIGS Solar Cells

Copper indium Gallium di-selenide or Cu(inGa)se 2 or CiGs is one of the best absorber

materials available owing to its high absorption coefficient and wide spectral response.

By adjusting the in and Ga ratio, we can adjust the band gap of the material from Cuinse 2

(1.1 eV) to CuGase 2 (1.68 eV). For CiGs, the substrate configuration gives the highest ef-

ficiency owing to favorable process conditions (Fig. 18.3). This configuration gives this

technology an added advantage of utilizing a range of substrates for the deposition of thin

films from rigid glass to flexible metal or polymeric foils. The downside of this technology

is the processing of the absorber at relatively higher temperatures >450°C. Also, the intro-

duction of alkali elements viz. Na, K into the thin film absorber stack provides an almost

3–4 folds increase in the efficiency which has been a “holy grail” for sometime in the thin

film field. Superstrate structures were investigated in early 80s but efficiency was below

FIGURE 18.3 Schematic presentation of CIGS solar cell in substrate configuration.