Page 136 - Adsorbents fundamentals and applications

P. 136

CARBON MOLECULAR SIEVES 121

A promising development in CMS membrane separation is the “selective

surface flow” carbon membranes, by Rao, Sircar, and co-workers (Rao et al.,

1992; Rao and Sircar, 1993a; Rao and Sircar, 1993b; Rao et al., 1994). Three

types of fluxes occur in pores: convective flux, Knudsen diffusion flux, and flux

by surface diffusion. Surface diffusion has been reviewed and discussed exten-

sively by Kapoor et al. (1989). When the surface concentration is high (e.g.,

for a strongly adsorbed component at a high concentration) or when the other

fluxes are low (e.g., in liquid phase), surface diffusion can become the dominant

flux for pore diffusion. Furthermore, when the pore dimension is about twice

that of the strongly adsorbed molecule, the (back-to-back) adsorbed molecules

effectively reduce the pore opening, thereby eliminating or hindering the fluxes

for the other non-adsorbed or weakly adsorbed molecules. The net result is

enhanced separation.

This concept of “selective surface flow” was first proposed in the 1950’s

when the effect one adsorbed species had on blocking the flux of another species

was lively discussed in the literature (e.g., Kammermeyer and Wyrick, 1958).

Kammermeyer and Wyrick (1958) studied the separation of propane and carbon

dioxide by a plug of porous glass, and enrichment factors as high as 100 for

propane were achieved. The separation was caused by differences in surface

fluxes because the gas-phase fluxes were about equal. However, the pores in

the porous glass were not small enough to achieve complete blockage by the

adsorbed molecules. This was achieved subsequently by Ash et al. (1963). Ash

et al. studied separations of four binary mixtures (H 2 /SO 2 ,N 2 /CO 2 ,Ne/CO 2 ,and

A/N 2 ) by a plug of carbon black powder that was highly compacted. They used

the case of H 2 /SO 2 for discussion, that the flux of H 2 would be enriched if the

carbon powder was not highly compacted. When it was highly compacted, the

enrichment was reversed, that is, SO 2 was enriched due to surface flow. Their

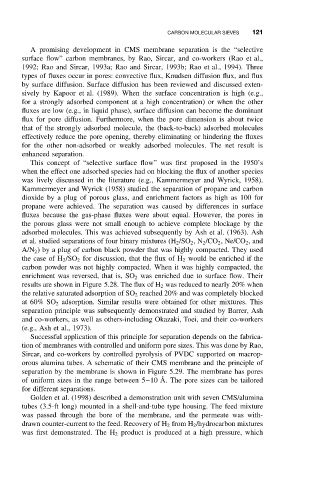

results are shown in Figure 5.28. The flux of H 2 was reduced to nearly 20% when

the relative saturated adsorption of SO 2 reached 20% and was completely blocked

at 60% SO 2 adsorption. Similar results were obtained for other mixtures. This

separation principle was subsequently demonstrated and studied by Barrer, Ash

and co-workers, as well as others-including Okazaki, Toei, and their co-workers

(e.g., Ash et al., 1973).

Successful application of this principle for separation depends on the fabrica-

tion of membranes with controlled and uniform pore sizes. This was done by Rao,

Sircar, and co-workers by controlled pyrolysis of PVDC supported on macrop-

orous alumina tubes. A schematic of their CMS membrane and the principle of

separation by the membrane is shown in Figure 5.29. The membrane has pores

of uniform sizes in the range between 5–10 ˚ A. The pore sizes can be tailored

for different separations.

Golden et al. (1998) described a demonstration unit with seven CMS/alumina

tubes (3.5-ft long) mounted in a shell-and-tube type housing. The feed mixture

was passed through the bore of the membrane, and the permeate was with-

drawn counter-current to the feed. Recovery of H 2 from H 2 /hydrocarbon mixtures

was first demonstrated. The H 2 product is produced at a high pressure, which