Page 171 - Adsorption, Ion Exchange & Catalysis- 2007, Elsevier - Copy

P. 171

Else_AIEC-INGLE_cH003.qxd 7/13/2006 1:45 PM Page 167

3.7 Three-Phase Fixed Beds: Trickle-Bed and Ped Bubble-Bed Reactors ack 167

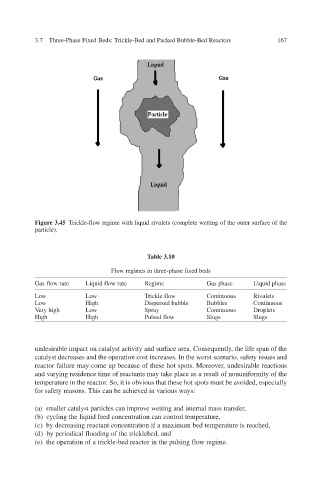

Figure 3.45 Trickle-flow regime with liquid rivulets (complete wetting of the outer surface of the

particle).

Table 3.10

ed beds ix Flow regimes in three-phase f

Gas flow rate Liquid flow rate Regime Gas phase Liquid phase

Low Low Trickle flow Continuous Rivulets

Low High Dispersed b ubble Bubbles Continuous

Very high Low Spray Continuous Droplets

High High Pulsed flow Slugs Slugs

undesirable impact on catalyst activity and surface area. Consequently, the life span of the

catalyst decreases and the operation cost increases. In the worst scenario, safety issues and

reactor failure may come up because of these hot spots. Moreo undesirable reactions , v er

and varying residence time of reactants may take place as a result of nonuniformity of the

temperature in the reactor. So, it is obespecially vious that these hot spots must be avoided,

for safety reasons. This can be achieed in v arious w v ays:

(a) smaller catalyst particles can impro e wetting and internal mass transfer, v

(b) cycling the liquid feed concentration can control temperature,

(c) by decreasing reactant concentration if a maximum bed temperature is reached,

(d) by periodical flooding of the tricklebed, and

(e) the operation of a trickle-bed reactor in the pulsing flo gime. w re