Page 127 - Advanced Gas Turbine Cycles

P. 127

Chapter 6. ‘Wet’ gas turbine plants 99

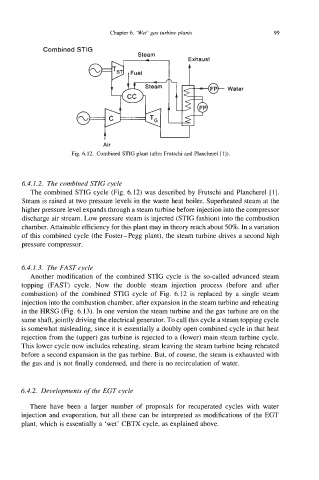

Combined STIG

Steam

Water

Air

Fig. 6.12. Combined STIG plant (after Frutschi and Plancherel [I]).

6.4.1.2. The combined STIG cycle

The combined STIG cycle (Fig. 6.12) was described by Frutschi and Plancherel [I].

Steam is raised at two pressure levels in the waste heat boiler. Superheated steam at the

higher pressure level expands through a steam turbine before injection into the compressor

discharge air stream. Low pressure steam is injected (STIG fashion) into the combustion

chamber. Attainable efficiency for this plant may in theory reach about 50%. In a variation

of this combined cycle (the Foster-Pegg plant), the steam turbine drives a second high

pressure compressor.

6.4.1.3. The FAST cycle

Another modification of the combined STIG cycle is the so-called advanced steam

topping (FAST) cycle. Now the double steam injection process (before and after

combustion) of the combined STIG cycle of Fig. 6.12 is replaced by a single steam

injection into the combustion chamber, after expansion in the steam turbine and reheating

in the HRSG (Fig. 6.13). In one version the steam turbine and the gas turbine are on the

same shaft, jointly driving the electrical generator. To call this cycle a steam topping cycle

is somewhat misleading, since it is essentially a doubly open combined cycle in that heat

rejection from the (upper) gas turbine is rejected to a (lower) main steam turbine cycle.

This lower cycle now includes reheating, steam leaving the steam turbine being reheated

before a second expansion in the gas turbine. But, of course, the steam is exhausted with

the gas and is not finally condensed, and there is no recirculation of water.

6.4.2. Developments of the EGT cycle

There have been a larger number of proposals for recuperated cycles with water

injection and evaporation, but all these can be interpreted as modifications of the EGT

plant, which is essentially a ‘wet’ CBTX cycle, as explained above.