Page 190 - Advanced Gas Turbine Cycles

P. 190

156 Advanced gas turbine cycles

C I

FUEL -

METHANE

EVAP EVAP CH4

IC AC

'

'

t TCR

1

HEAT

EXHAUST EXCHANGER

TO STACK 1

[COz,Nz,0zJWl WATER

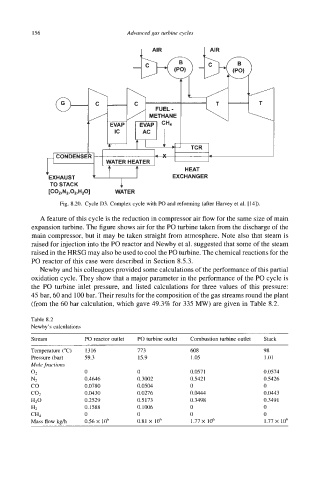

Fig. 8.20. Cycle D3. Complex cycle with PO and reforming (after Harvey et al. [14]).

A feature of this cycle is the reduction in compressor air flow for the same size of main

expansion turbine. The figure shows air for the PO turbine taken from the discharge of the

main compressor, but it may be taken straight from atmosphere. Note also that steam is

raised for injection into the PO reactor and Newby et al. suggested that some of the steam

raised in the HRSG may also be used to cool the PO turbine. The chemical reactions for the

PO reactor of this case were described in Section 8.5.3.

Newby and his colleagues provided some calculations of the performance of this partial

oxidation cycle. They show that a major parameter in the performance of the PO cycle is

the Po turbine inlet pressure, and listed calculations for three values of this pressure:

45 bar, 60 and 100 bar. Their results for the composition of the gas streams round the plant

(from the 60 bar calculation, which gave 49.3% for 335 MW) are given in Table 8.2.

Table 8.2

Newby's calculations

Stream PO reactor outlet PO turbine outlet Combustion turbine outlet Stack

Temperature ("C) 1316 773 608 98

Pressure (bar) 59.3 15.9 1.05 1.01

Mole fractions

02 0 0 0.057 1 0.0574

Nz 0.4646 0.3002 0.5421 0.5426

co 0.0780 0.0504 0 0

coz 0.0430 0.0276 0.0444 0.0443

H20 0.2529 0.5173 0.3498 0.349 I

HZ 0.1588 0.1006 0 0

CH4 0 0 0 0

Mass flow kgh 0.56 X 10' 0.81 X 10' 1.77 X IO6 1.77 X 10'