Page 185 - Advanced Gas Turbine Cycles

P. 185

Chapter 8. Novel gas turbine cycles 151

ABSORPTION,

C02 FREE EXHAUST

EXCHANGER

EXHAUST TO

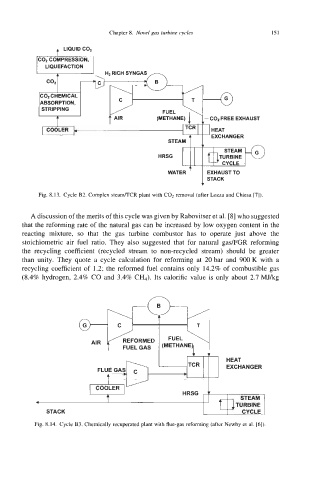

Fig. 8.13. Cycle 92. Complex steam/TCR plant with COl removal (after Lozza and Chiesa [7]).

A discussion of the merits of this cycle was given by Rabovitser et al. [8] who suggested

that the reforming rate of the natural gas can be increased by low oxygen content in the

reacting mixture, so that the gas turbine combustor has to operate just above the

stoichiometric air fuel ratio. They also suggested that for natural gas/FGR reforming

the recycling coefficient (recycled stream to non-recycled stream) should be greater

than unity. They quote a cycle calculation for reforming at 20 bar and 900K with a

recycling coefficient of 1.2; the reformed fuel contains only 14.2% of combustible gas

(8.4% hydrogen, 2.4% CO and 3.4% Ch). Its calorific value is only about 2.7 MJkg

STEAM

TURBINE

STACK L w CYCLE

Fig. 8.14. Cycle B3. Chemically recuperated plant with flue-gas reforming (after Newby et al. [SI).