Page 181 - Advanced Gas Turbine Cycles

P. 181

Chapter 8. Novel gas turbine cycles I47

the scrubbing process to intercool and aftercool the compression in the gas turbine

cycle can restore about half the loss in thermal efficiency. After a very careful

optimisation, and by including amine regeneration, Corti and Manfrida estimated the

cost of electricity generated by this plant, including COz disposal, to be about 4.7 c/

kWh. This is slightly less than the estimate of Chiesa and Consonni who based their

calculations on different sources.

Fig. 8.8 shows yet another example (Cycle A3) of the use of the semi-closed cycle

concept, suggested by Manfrida [4], in which a recuperative CBTX plant is modified. Now

the exhaust gas from the gas turbine is cooled in a heat exchanger (rather than the HRSG of

a CCGT plant). It then enters the chemical absorption plant where some C02 is

sequestrated and liquefied before disposal. The remainder of the exhaust gas is recirculated

into compressor inlet after additional cooling. Manfrida finds slightly lower efficiency in

the plant A3 compared with plant A2, but argues that it may prove simpler and more

economic than the semi-closed IGCC plant.

8.6.2. Cycles B with modijication of the fuel in combustion through thermo-chemical

recuperation [TCR]

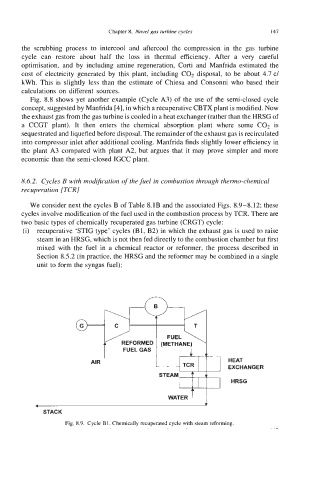

We consider next the cycles B of Table 8.1B and the associated Figs. 8.9-8.12; these

cycles involve modification of the fuel used in the combustion process by TCR. There are

two basic types of chemically recuperated gas turbine (CRGT) cycle:

(i) recuperative ‘STIG type’ cycles (Bl, B2) in which the exhaust gas is used to raise

steam in an HRSG, which is not then fed directly to the combustion chamber but first

mixed with the fuel in a chemical reactor or reformer, the process described in

Section 8.5.2 (in practice, the HRSG and the reformer may be combined in a single

unit to form the syngas fuel);

FUEL \

I (METHANE)

AIR FUELGAS HEAT

1 EXCHANGER

I

HRSG

- WATER

STACK

Fig. 8.9. Cycle B1. Chemically recuperated cycle with steam reforming.