Page 180 - Advanced Gas Turbine Cycles

P. 180

146 Advanced gas turbine cycles

FUEL (METHANE)

1

\

ABSORPTION,

STRIPPING,

ILIQUEFACTION rAJ HEAT EXCHANGER

HEAT~N

1

LIQUID COz

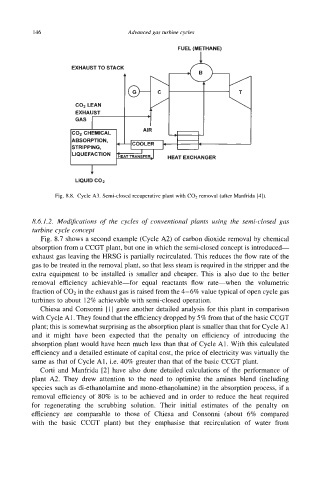

Fig. 8.8. Cycle A3. Semi-closed recuperative plant with COz removal (after hkdnfrida 141).

8.6. I .2. Mod$cations of the cycles of conventional plants using the semi-closed gas

turbine cycle concept

Fig. 8.7 shows a second example (Cycle A2) of carbon dioxide removal by chemical

absorption from a CCGT plant, but one in which the semi-closed concept is introduced-

exhaust gas leaving the HRSG is partially recirculated. This reduces the flow rate of the

gas to be treated in the removal plant, so that less steam is required in the stripper and the

extra equipment to be installed is smaller and cheaper. This is also due to the better

removal efficiency achievable-for equal reactants flow rate-when the volumetric

fraction of C02 in the exhaust gas is raised from the 4-6% value typical of open cycle gas

turbines to about 12% achievable with semi-closed operation.

Chiesa and Consonni [I] gave another detailed analysis for this plant in comparison

with Cycle AI. They found that the efficiency dropped by 5% from that of the basic CCGT

plant; this is somewhat surprising as the absorption plant is smaller than that for Cycle A1

and it might have been expected that the penalty on efficiency of introducing the

absorption plant would have been much less than that of Cycle Al. With this calculated

efficiency and a detailed estimate of capital cost, the price of electricity was virtually the

same as that of Cycle Al, Le. 40% greater than that of the basic CCGT plant.

Corti and Manfrida [2] have also done detailed calculations of the performance of

plant A2. They drew attention to the need to optimise the amines blend (including

species such as di-ethanolamine and mono-ethanolamine) in the absorption process, if a

removal efficiency of 80% is to be achieved and in order to reduce the heat required

for regenerating the scrubbing solution. Their initial estimates of the penalty on

efficiency are comparable to those of Chiesa and Consonni (about 6% compared

with the basic CCGT plant) but they emphasise that recirculation of water from