Page 183 - Advanced Gas Turbine Cycles

P. 183

Chapter 8. Novel gas turbine cycles 149

41 -

(ii) a semi-closed cycle (B3) in which part of the exhaust gas is recirculated to the

reformer, together with the fuel supply, to form a new syngas fuel (the process

described in Section 8.5.4).

In both cases heat is taken from the exhaust gases to ‘feed’ the reaction process,

enhancing the ‘heating value’ of the resulting modified fuel, which is then fed to the

combustion chamber. But the main thermodynamic feature is that the exergy loss in the

final exhaust gas is thus reduced and the efficiency increased.

8.6.2.1. The steanuTCR cycle

Fig. 8.9 shows a chemically recuperated cycle [Bl] of the first type, i.e. chemical

recuperation with steam reforming (steam/TCR).

We first refer back to Section 6.2.2, which gave a simplified first law of analysis of a

modified STTG type cycle presented by Lloyd [5]. He described an additional heat

exchanger in the STIG cycle raising the enthalpy of the air entering the combustion

chamber. The exhaust gas from the turbine thus first passed through this recuperator,

effectively reducing the external ‘heat supplied’ to the combustion chamber. Lloyd argued

that the heat transferred in the reformer of the steam/TCR plant performs a similar function

to that of the recuperator in the modified STIG cycle. Lloyd’s point is illustrated in

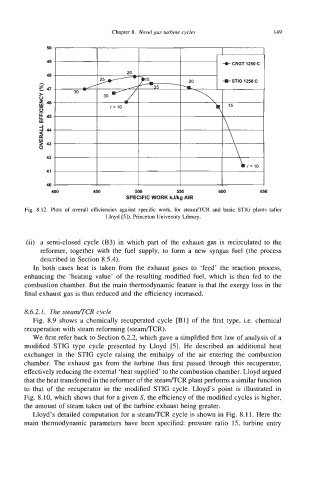

Fig. 8.10, which shows that for a given S, the efficiency of the modified cycles is higher,

the amount of steam taken out of the turbine exhaust being greater.

Lloyd’s detailed computation for a steam/TCR cycle is shown in Fig. 8. I 1. Here the

main thermodynamic parameters have been specified: pressure ratio 15, turbine entry