Page 193 - Advances in bioenergy (2016)

P. 193

biodegradable, and low in toxicity; (2) they can be easily decomposed in the presence of water

to generate a hydrogen-rich mixture; and (3) they are free from catalyst toxins such as sulfur.

This review has emphasized on hydrogen generation via pyrolysis of biomass, gasification,

gasification combined with pyrolysis, from supercritical water (fluid-gas) extraction. Steam

reforming (SR), autothermal reforming (ATR), dry reforming (DR), liquid phase reforming

(LPR), aqueous-phase reforming (APR) and partial oxidation (POX) of renewable

carboxylates, such as bioethanol, glycerol, carbohydrates, and bio-oil are some usual

processes to be explored for their widespread awareness. Among all these processes SR is

endothermic, (T > 300°C); for LPR, high pressure and T < 300°C are required; for ATR, both

partial oxidation and steam reforming in the temperature range of (550°C < T < 850°C) are

necessary. However, supercritical reforming always occurs at high pressure and at T > 374°C,

and to carry out photocatalytic conversion T ≈ 25°C is appropriate. 19-23

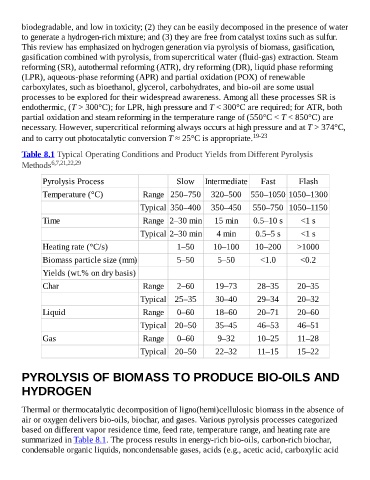

Table 8.1 Typical Operating Conditions and Product Yields from Different Pyrolysis

Methods 6,7,21,22,29

Pyrolysis Process Slow Intermediate Fast Flash

Temperature (°C) Range 250–750 320–500 550–1050 1050–1300

Typical 350–400 350–450 550–750 1050–1150

Time Range 2–30 min 15 min 0.5–10 s <1 s

Typical 2–30 min 4 min 0.5–5 s <1 s

Heating rate (°C/s) 1–50 10–100 10–200 >1000

Biomass particle size (mm) 5–50 5–50 <1.0 <0.2

Yields (wt.% on dry basis)

Char Range 2–60 19–73 28–35 20–35

Typical 25–35 30–40 29–34 20–32

Liquid Range 0–60 18–60 20–71 20–60

Typical 20–50 35–45 46–53 46–51

Gas Range 0–60 9–32 10–25 11–28

Typical 20–50 22–32 11–15 15–22

PYROLYSIS OF BIOMASS TO PRODUCE BIO-OILS AND

HYDROGEN

Thermal or thermocatalytic decomposition of ligno(hemi)cellulosic biomass in the absence of

air or oxygen delivers bio-oils, biochar, and gases. Various pyrolysis processes categorized

based on different vapor residence time, feed rate, temperature range, and heating rate are

summarized in Table 8.1. The process results in energy-rich bio-oils, carbon-rich biochar,

condensable organic liquids, noncondensable gases, acids (e.g., acetic acid, carboxylic acid