Page 381 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 381

360 12 Carbon Capture and Storage

Although it is only estimation, the comparison does show that the oxyfuel

combustion flame temperature is higher than that of conventional combustion with

air. As a result, the boiler of the oxyfuel combustion process requires special

materials that can survive extreme temperature.

Another concern of the oxyfuel combustion process with sulfur containing fuels

is the high SO x concentration without the dilution of nitrogen, resulting in high

corrosion on the ducts. Extra costs are associated with concentrated oxygen pro-

duction by costly air separation units.

The benefit is a simple process for carbon capture after combustion. Without

nitrogen and NO x in the flue gas, it contains mainly H 2 O and CO 2 . After the

removal of soot and SO 2 , if any, CO 2 can be readily separated from water vapor by

condensation in a cooler. This highly concentrated CO 2 is ready for transportation

and storage.

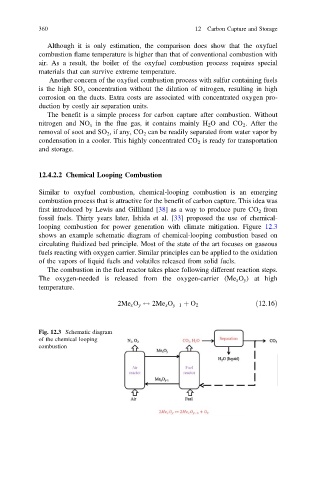

12.4.2.2 Chemical Looping Combustion

Similar to oxyfuel combustion, chemical-looping combustion is an emerging

combustion process that is attractive for the benefit of carbon capture. This idea was

first introduced by Lewis and Gilliland [38] as a way to produce pure CO 2 from

fossil fuels. Thirty years later, Ishida et al. [33] proposed the use of chemical-

looping combustion for power generation with climate mitigation. Figure 12.3

shows an example schematic diagram of chemical-looping combustion based on

circulating fluidized bed principle. Most of the state of the art focuses on gaseous

fuels reacting with oxygen carrier. Similar principles can be applied to the oxidation

of the vapors of liquid fuels and volatiles released from solid fuels.

The combustion in the fuel reactor takes place following different reaction steps.

The oxygen-needed is released from the oxygen-carrier (Me x O y ) at high

temperature.

2Me x O y $ 2Me x O y 1 þ O 2 ð12:16Þ

Fig. 12.3 Schematic diagram

of the chemical looping

combustion