Page 161 -

P. 161

PRODUCTION MANAGEMENT APPLICATIONS 141

The Janders Company markets various business and engineering products across

Europe. Currently, Janders is preparing to introduce two new PDAs (Personal

Digital Assistant): one for the business market called the Financial Manager and

one for the engineering market called the Technician. Each PDA has three compo-

nents: a base, an electronic cartridge and a faceplate or top. The same base is used

for both products, but the cartridges and tops are different. All components can be

manufactured by the company or purchased from outside suppliers. The manu-

facturing costs and purchase prices for the components are summarized in Table 4.1.

Company forecasters indicate that 3000 Financial Manager PDAs and 2000

Technician PDAs will be needed for the next production period. However, manu-

facturing capacity is limited. The company has 200 hours of regular manufacturing

time and 50 hours of overtime that can be scheduled for the calculators. Overtime

involves a premium at the additional cost of E9 per hour. Table 4.2 shows manu-

facturing times (in minutes) for the components.

Let us apply our formulation process outlined in Section 4.1. We already have a

description of the problem. Given that we have information on costs, then it seems

likely that a suitable objective will be to minimize production costs for the two

products. A number of constraints become apparent: we must produce enough of

the two types of PDA to meet forecasted demand; there is limited regular manu-

facturing time; there is limited overtime. The decision variables are then the quanti-

ties of the five components that we either manufacture ourselves or that we buy in

from our suppliers and we show these as follows:

BM ¼ number of bases manufactured

BP ¼ number of bases purchased

FCM ¼ number of Financial cartridges manufactured

FCP ¼ number of Financial cartridges purchased

TCM ¼ number of Technician cartridges manufactured

TCP ¼ number of Technician cartridges purchased

FTM ¼ number of Financial tops manufactured

FTP ¼ number of Financial tops purchased

TTM ¼ number of Technician tops manufactured

TTP ¼ number of Technician tops purchased

One additional decision variable is needed to determine the hours of overtime that

must be scheduled:

OT ¼ number of hours of overtime to be scheduled

The objective function is to minimize the total cost, including manufacturing costs,

purchase costs and overtime costs. Using the cost-per-unit data in Table 4.1 and

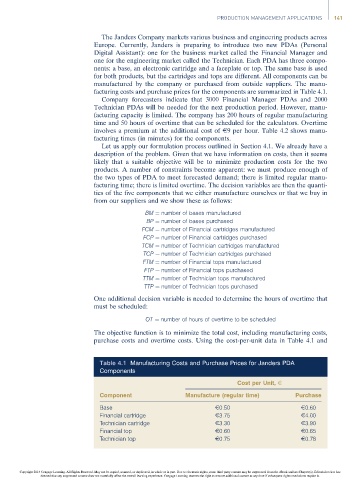

Table 4.1 Manufacturing Costs and Purchase Prices for Janders PDA

Components

Cost per Unit, E

Component Manufacture (regular time) Purchase

Base E0.50 E0.60

Financial cartridge E3.75 E4.00

Technician cartridge E3.30 E3.90

Financial top E0.60 E0.65

Technician top E0.75 E0.78

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.