Page 165 -

P. 165

PRODUCTION MANAGEMENT APPLICATIONS 145

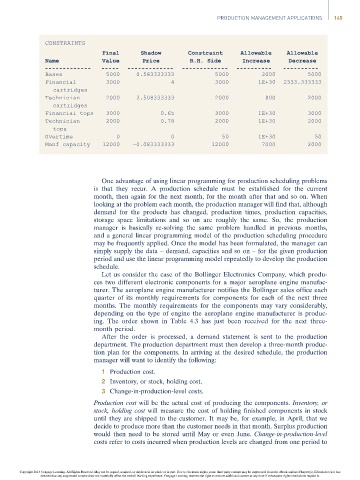

CONSTRAINTS

Final Shadow Constraint Allowable Allowable

Name Value Price R.H. Side Increase Decrease

------------- ----- ------------- ------------- ---------- ----------

Bases 5000 0.583333333 5000 2000 5000

Financial 3000 4 3000 1E+30 2333.333333

cartridges

Technician 2000 3.508333333 2000 800 2000

cartridges

Financial tops 3000 0.65 3000 1E+30 3000

Technician 2000 0.78 2000 1E+30 2000

tops

Overtime 0 0 50 1E+30 50

Manf capacity 12000 -0.083333333 12000 7000 2000

One advantage of using linear programming for production scheduling problems

is that they recur. A production schedule must be established for the current

month, then again for the next month, for the month after that and so on. When

looking at the problem each month, the production manager will find that, although

demand for the products has changed, production times, production capacities,

storage space limitations and so on are roughly the same. So, the production

manager is basically re-solving the same problem handled in previous months,

and a general linear programming model of the production scheduling procedure

may be frequently applied. Once the model has been formulated, the manager can

simply supply the data – demand, capacities and so on – for the given production

period and use the linear programming model repeatedly to develop the production

schedule.

Let us consider the case of the Bollinger Electronics Company, which produ-

ces two different electronic components for a major aeroplane engine manufac-

turer. The aeroplane engine manufacturer notifies the Bollinger sales office each

quarter of its monthly requirements for components for each of the next three

months. The monthly requirements for the components may vary considerably,

depending on the type of engine the aeroplane engine manufacturer is produc-

ing. The order shown in Table 4.3 has just been received for the next three-

month period.

After the order is processed, a demand statement is sent to the production

department. The production department must then develop a three-month produc-

tion plan for the components. In arriving at the desired schedule, the production

manager will want to identify the following:

1 Production cost.

2 Inventory, or stock, holding cost.

3 Change-in-production-level costs.

Production cost will be the actual cost of producing the components. Inventory, or

stock, holding cost will measure the cost of holding finished components in stock

until they are shipped to the customer. It may be, for example, in April, that we

decide to produce more than the customer needs in that month. Surplus production

would then need to be stored until May or even June. Change-in-production-level

costs refer to costs incurred when production levels are changed from one period to

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.