Page 166 -

P. 166

146 CHAPTER 4 LINEAR PROGRAMMING APPLICATIONS

another. Increasing production, for example, may need extra staff, extra supplies;

decreasing production may mean laying off staff temporarily and cancelling supplies

that have been ordered. Such short-term actions may cost the company money.

In the remainder of this section, we show how to formulate a linear programming

model of the production and inventory process for Bollinger Electronics to minimize

the total cost.

To develop the model, we let x im denote the production volume in units for

product i in month m. Here i ¼ 1, 2, and m ¼ 1, 2, 3; i ¼ 1 refers to component

322A, i ¼ 2 refers to component 802B, m ¼ 1 refers to April, m ¼ 2 refers to May

and m ¼ 3 refers to June. The purpose of the double subscript is to provide a more

descriptive notation. We could simply use x 6 to represent the number of units of

product 2 produced in month 3, but x 23 is more descriptive, identifying directly the

product and month represented by the variable.

Component 322A costs E20 per unit produced and component 802B costs E10

per unit produced, so the total production cost part of the objective function is:

Total production cost ¼ 20x 11 þ 20x 12 þ 20x 13 þ 10x 21 þ 10x 22 þ 10x 23

Because the production cost per unit is the same each month, we don’t need to

include the production costs in the objective function; that is, regardless of the

production schedule selected, the total production cost will remain the same. In

other words, production costs are not relevant costs for the production scheduling

decision under consideration. In cases in which the production cost per unit is

expected to change each month, the variable production costs per unit per month

must be included in the objective function. The solution for the Bollinger Elec-

tronics problem will be the same whether these costs are included, therefore we

include them so that the value of the linear programming objective function will

include all the costs associated with the problem.

To incorporate the relevant inventory holding costs into the model, we let s im

denote the inventory level for product i at the end of month m. Bollinger determined

that on a monthly basis inventory holding costs are 1.5 per cent of the cost of the

product; that is, (0.015)(E20) ¼ E0.30 per unit for component 322A and

(0.015)(E10) ¼ E0.15 per unit for component 802B. A common assumption made

in using the linear programming approach to production scheduling is that monthly

ending inventories are an acceptable approximation to the average inventory levels

throughout the month. Making this assumption, we write the inventory holding cost

portion of the objective function as:

Inventory holding cost ¼ 0:30s 11 þ 0:30s 12 þ 0:30s 13 þ 0:15s 21 þ 0:15s 22 þ 0:15s 23

To incorporate the costs of fluctuations in production levels from month to month,

we need to define two additional variables:

I m ¼ increase in the total production level necessary during month m

D m ¼ decrease in the total production level necessary during month m

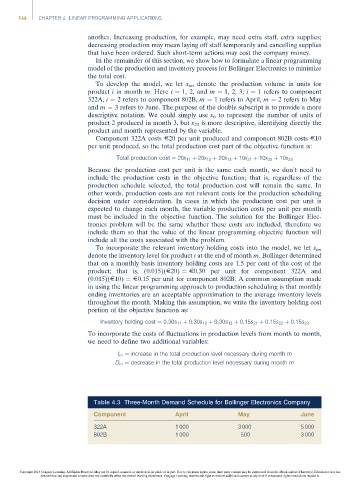

Table 4.3 Three-Month Demand Schedule for Bollinger Electronics Company

Component April May June

322A 1 000 3 000 5 000

802B 1 000 500 3 000

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.