Page 437 -

P. 437

ECONOMIC PRODUCTION LOT SIZE MODEL 417

To illustrate we shall use the following example. EnviroHealth, a large pharma-

ceutical company, manufactures a special type of anti-bacterial soap used in local

health clinics. The soap is sold in one litre bottles and because of the specialist

nature of the product and the strict hygiene controls that are enforced during

production, the soap is produced only at limited times and not continuously. The

company estimates that its current maximum annual production capacity is 60 000

litres. Current annual demand is 26 000 litres and is fairly constant through the year.

Given that the company will not be producing the product continuously through the

year it needs to know how often to produce the product and how much of the

product to produce each time.

For example, if we have a production system that produces 50 units per day and

we decide to schedule ten days of production, we have a 50(10) ¼ 500-unit produc-

tion lot size. The lot size is the number of units in an order. In general, if we let Q

indicate the production lot size, the approach to the inventory decisions is similar to

the EOQ model; that is, we build a holding and ordering cost model that expresses

the total cost as a function of the production lot size. Then we attempt to find the

production lot size that minimizes the total cost.

One other condition that should be mentioned at this time is that the model only

applies to situations where the production rate is greater than the demand rate; the

production system must be able to satisfy demand. For instance, if the constant

demand rate is 400 units per day, the production rate must be at least 400 units per

day to satisfy demand. For EnviroHealth, this requirement is satisfied: annual

production capacity is 60 000 litres whilst annual demand is only 26 000.

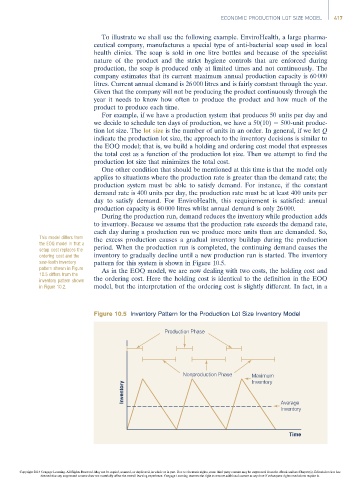

During the production run, demand reduces the inventory while production adds

to inventory. Because we assume that the production rate exceeds the demand rate,

each day during a production run we produce more units than are demanded. So,

This model differs from the excess production causes a gradual inventory buildup during the production

the EOQ model in that a

setup cost replaces the period. When the production run is completed, the continuing demand causes the

ordering cost and the inventory to gradually decline until a new production run is started. The inventory

saw-tooth inventory pattern for this system is shown in Figure 10.5.

pattern shown in Figure As in the EOQ model, we are now dealing with two costs, the holding cost and

10.5 differs from the

inventory pattern shown the ordering cost. Here the holding cost is identical to the definition in the EOQ

in Figure 10.2. model, but the interpretation of the ordering cost is slightly different. In fact, in a

Figure 10.5 Inventory Pattern for the Production Lot Size Inventory Model

Production Phase

Nonproduction Phase Maximum

Inventory

Inventory

Average

Inventory

Time

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.