Page 441 -

P. 441

INVENTORY MODEL WITH PLANNED SHORTAGES 421

10.4 Inventory Model with Planned Shortages

A shortage or stock-out is a demand that cannot be supplied. In many situations,

shortages are undesirable and should be avoided if at all possible. However, in other

cases it may be desirable – from an economic point of view – to plan for and allow

shortages. In practice, these types of situations are most commonly found where the

value of the inventory per unit is high and hence the holding cost is high. An example

of this type of situation is a new car dealer’s inventory. Often the specific car that a

customer wants is not in stock. However, if the customer is willing to wait a few weeks,

the dealer is usually able to order the car for delivery at some stage in the future.

The assumptions of the The model developed in this section takes into account a type of shortage known

EOQ model in Table 10.3 as a backorder. In a backorder situation, we assume that when a customer places an

apply to this inventory

model with the exception order and discovers that the supplier is out of stock, the customer waits until the new

that shortages, referred shipment arrives, and then the order is filled. Frequently, the waiting period in back-

to as backorders, are ordering situations is relatively short. So, by promising the customer top priority and

now permitted.

immediate delivery when the goods become available, companies may be able to

convince the customer to wait until the order arrives. In these cases, the backorder

assumption is valid.

The backorder model that we develop is an extension of the EOQ model pre-

sented in Section 10.2. We use the EOQ model in which all goods arrive in inventory

at one time and are subject to a constant demand rate. If we let S indicate the

number of backorders that are accumulated when a new shipment of size Q is

received, then the inventory system for the backorder case has the following char-

acteristics:

l If S backorders exist when a new shipment of size Q arrives, then S backorders

are shipped to the appropriate customers and the remaining Q S units are

placed in inventory. Therefore, Q S is the maximum inventory.

l The inventory cycle of T days is divided into two distinct phases: t 1 days when

inventory is available and orders are filled as they occur, and t 2 days when

stock-outs occur and all new orders are placed on backorder.

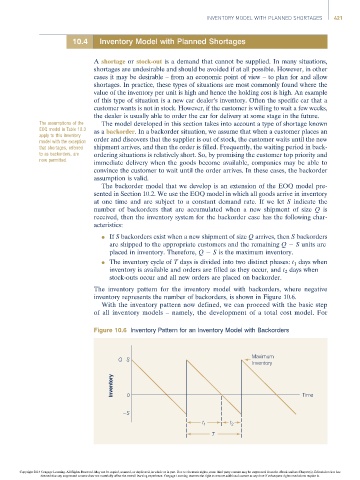

The inventory pattern for the inventory model with backorders, where negative

inventory represents the number of backorders, is shown in Figure 10.6.

With the inventory pattern now defined, we can proceed with the basic step

of all inventory models – namely, the development of a total cost model. For

Figure 10.6 Inventory Pattern for an Inventory Model with Backorders

Maximum

Q – S

Inventory

Inventory 0 Time

– S

t 1 t 2

T

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.