Page 108 - An Introduction to Microelectromechanical Systems Engineering

P. 108

Passive Micromachined Mechanical Structures 87

Silicon

Adhesive

Silicon

Outlet

(a)

Inlet

Silicon Outlet

(b)

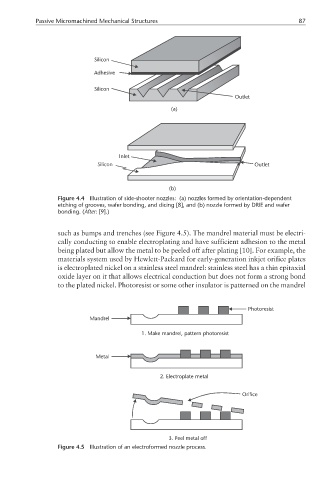

Figure 4.4 Illustration of side-shooter nozzles: (a) nozzles formed by orientation-dependent

etching of grooves, wafer bonding, and dicing [8], and (b) nozzle formed by DRIE and wafer

bonding. (After: [9].)

such as bumps and trenches (see Figure 4.5). The mandrel material must be electri-

cally conducting to enable electroplating and have sufficient adhesion to the metal

being plated but allow the metal to be peeled off after plating [10]. For example, the

materials system used by Hewlett-Packard for early-generation inkjet orifice plates

is electroplated nickel on a stainless steel mandrel: stainless steel has a thin epitaxial

oxide layer on it that allows electrical conduction but does not form a strong bond

to the plated nickel. Photoresist or some other insulator is patterned on the mandrel

Photoresist

Mandrel

1. Make mandrel, pattern photoresist

Metal

2. Electroplate metal

Orifice

3. Peel metal off

Figure 4.5 Illustration of an electroformed nozzle process.