Page 111 - An Introduction to Microelectromechanical Systems Engineering

P. 111

90 MEM Structures and Systems in Industrial and Automotive Applications

Bondpad

{100} Si P-type diffused

diaphragm piezoresistor Metal conductors

N-type

epitaxial

R

R 2 1 layer

R 3

P-type

{111} substrate

and frame

Anodically

bonded

Etched cavity Pyrex substrate

Backside port

(a)

R

1 R 2

V bridge

R 3 R 4 V out

(b)

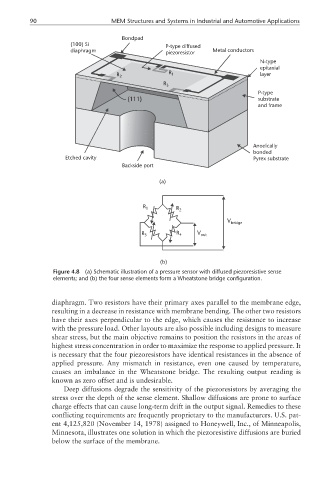

Figure 4.8 (a) Schematic illustration of a pressure sensor with diffused piezoresistive sense

elements; and (b) the four sense elements form a Wheatstone bridge configuration.

diaphragm. Two resistors have their primary axes parallel to the membrane edge,

resulting in a decrease in resistance with membrane bending. The other two resistors

have their axes perpendicular to the edge, which causes the resistance to increase

with the pressure load. Other layouts are also possible including designs to measure

shear stress, but the main objective remains to position the resistors in the areas of

highest stress concentration in order to maximize the response to applied pressure. It

is necessary that the four piezoresistors have identical resistances in the absence of

applied pressure. Any mismatch in resistance, even one caused by temperature,

causes an imbalance in the Wheatstone bridge. The resulting output reading is

known as zero offset and is undesirable.

Deep diffusions degrade the sensitivity of the piezoresistors by averaging the

stress over the depth of the sense element. Shallow diffusions are prone to surface

charge effects that can cause long-term drift in the output signal. Remedies to these

conflicting requirements are frequently proprietary to the manufacturers. U.S. pat-

ent 4,125,820 (November 14, 1978) assigned to Honeywell, Inc., of Minneapolis,

Minnesota, illustrates one solution in which the piezoresistive diffusions are buried

below the surface of the membrane.