Page 116 - An Introduction to Microelectromechanical Systems Engineering

P. 116

Sensors and Analysis Systems 95

provides a fast thermal time constant and consequently a rapid response time. One

approach to inferring the temperature of the heating element is to drive it with a

constant current and measure its resistance, then calculate the temperature using the

TCR. Alternatively, direct temperature measurement using a p-n diode or a thermo-

couple is equally adequate.

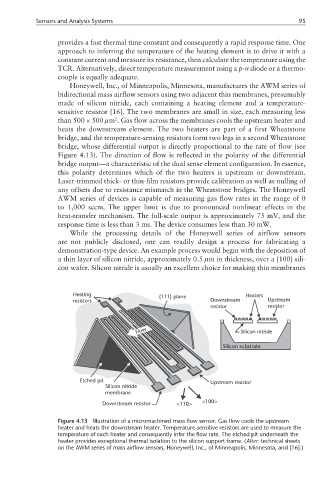

Honeywell, Inc., of Minneapolis, Minnesota, manufactures the AWM series of

bidirectional mass airflow sensors using two adjacent thin membranes, presumably

made of silicon nitride, each containing a heating element and a temperature-

sensitive resistor [16]. The two membranes are small in size, each measuring less

2

than 500 × 500 µm . Gas flow across the membranes cools the upstream heater and

heats the downstream element. The two heaters are part of a first Wheatstone

bridge, and the temperature-sensing resistors form two legs in a second Wheatstone

bridge, whose differential output is directly proportional to the rate of flow (see

Figure 4.13). The direction of flow is reflected in the polarity of the differential

bridge output—a characteristic of the dual sense element configuration. In essence,

this polarity determines which of the two heaters is upstream or downstream.

Laser-trimmed thick- or thin-film resistors provide calibration as well as nulling of

any offsets due to resistance mismatch in the Wheatstone bridges. The Honeywell

AWM series of devices is capable of measuring gas flow rates in the range of 0

to 1,000 sccm. The upper limit is due to pronounced nonlinear effects in the

heat-transfer mechanism. The full-scale output is approximately 75 mV, and the

response time is less than 3 ms. The device consumes less than 30 mW.

While the processing details of the Honeywell series of airflow sensors

are not publicly disclosed, one can readily design a process for fabricating a

demonstration-type device. An example process would begin with the deposition of

a thin layer of silicon nitride, approximately 0.5 µm in thickness, over a {100} sili-

con wafer. Silicon nitride is usually an excellent choice for making thin membranes

Heating

{111} plane Heaters

resistors Downstream Upstream

resistor resistor

Flow Silicon nitride

Silicon substrate

Etched pit Upstream resistor

Silicon nitride

membrane

Downstream resistor <110> <100>

Figure 4.13 Illustration of a micromachined mass flow sensor. Gas flow cools the upstream

heater and heats the downstream heater. Temperature-sensitive resistors are used to measure the

temperature of each heater and consequently infer the flow rate. The etched pit underneath the

heater provides exceptional thermal isolation to the silicon support frame. (After: technical sheets

on the AWM series of mass airflow sensors, Honeywell, Inc., of Minneapolis, Minnesota, and [16].)