Page 115 - An Introduction to Microelectromechanical Systems Engineering

P. 115

94 MEM Structures and Systems in Industrial and Automotive Applications

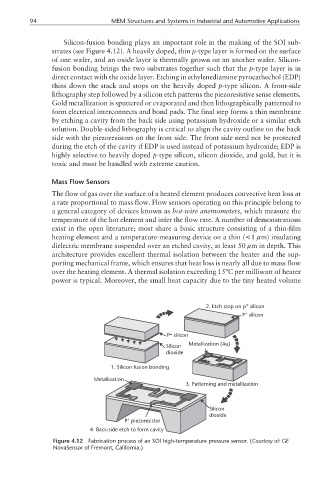

Silicon-fusion bonding plays an important role in the making of the SOI sub-

strates (see Figure 4.12). A heavily doped, thin p-type layer is formed on the surface

of one wafer, and an oxide layer is thermally grown on an another wafer. Silicon-

fusion bonding brings the two substrates together such that the p-type layer is in

direct contact with the oxide layer. Etching in ethylenediamine pyrocathechol (EDP)

thins down the stack and stops on the heavily doped p-type silicon. A front-side

lithography step followed by a silicon etch patterns the piezoresistive sense elements.

Gold metallization is sputtered or evaporated and then lithographically patterned to

form electrical interconnects and bond pads. The final step forms a thin membrane

by etching a cavity from the back side using potassium hydroxide or a similar etch

solution. Double-sided lithography is critical to align the cavity outline on the back

side with the piezoresistors on the front side. The front side need not be protected

during the etch of the cavity if EDP is used instead of potassium hydroxide; EDP is

highly selective to heavily doped p-type silicon, silicon dioxide, and gold, but it is

toxic and must be handled with extreme caution.

Mass Flow Sensors

The flow of gas over the surface of a heated element produces convective heat loss at

a rate proportional to mass flow. Flow sensors operating on this principle belong to

a general category of devices known as hot-wire anemometers, which measure the

temperature of the hot element and infer the flow rate. A number of demonstrations

exist in the open literature; most share a basic structure consisting of a thin-film

heating element and a temperature-measuring device on a thin (<1 µm) insulating

dielectric membrane suspended over an etched cavity, at least 50 µm in depth. This

architecture provides excellent thermal isolation between the heater and the sup-

porting mechanical frame, which ensures that heat loss is nearly all due to mass flow

over the heating element. A thermal isolation exceeding 15ºC per milliwatt of heater

power is typical. Moreover, the small heat capacity due to the tiny heated volume

+

2. Etch stop on p silicon

+

P silicon

+

P silicon

Metallization (Au)

Silicon

dioxide

1. Silicon fusion bonding

Metallization

3. Patterning and metallization

Silicon

dioxide

+

P piezoresistor

4. Back-side etch to form cavity

Figure 4.12 Fabrication process of an SOI high-temperature pressure sensor. (Courtesy of: GE

NovaSensor of Fremont, California.)