Page 119 - An Introduction to Microelectromechanical Systems Engineering

P. 119

98 MEM Structures and Systems in Industrial and Automotive Applications

reach a dynamic peak of 10,000G! In addition to achieving a large impact, the drop

test excites the various modes of resonance that are liable to cause catastrophic

failure.

While many companies offer micromachined acceleration sensor products, a

representative set of only four accelerometers follows next, each unique in its design

and fabrication.

Piezoresistive Bulk Micromachined Accelerometer

Until only recently, piezoresistive-type acceleration sensors were widely available.

Many companies, including GE NovaSensor of Fremont, California, and IC Sensors

of San Jose, California (a division of Measurement Specialties, Inc., of Fairfield,

New Jersey), offered products using anisotropically etched silicon inertial mass and

diffused piezoresistive sense elements. But these products were retired because they

could not meet the aggressive pricing requirements of the automotive industry. The

product introduction in 1996 by Endevco Corp., of San Juan Capistrano, Califor-

nia, indicates that piezoresistive accelerometers remain in this highly competitive

market (see Figure 4.15).

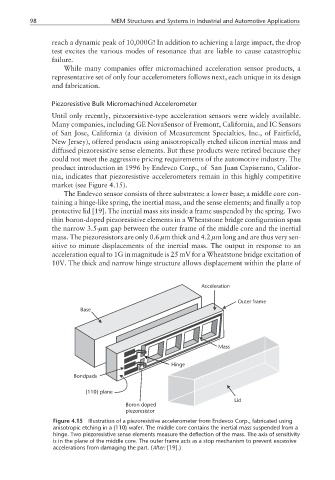

The Endevco sensor consists of three substrates: a lower base; a middle core con-

taining a hinge-like spring, the inertial mass, and the sense elements; and finally a top

protective lid [19]. The inertial mass sits inside a frame suspended by the spring. Two

thin boron-doped piezoresistive elements in a Wheatstone bridge configuration span

the narrow 3.5-µm gap between the outer frame of the middle core and the inertial

mass. The piezoresistors are only 0.6 µm thick and 4.2 µm long and are thus very sen-

sitive to minute displacements of the inertial mass. The output in response to an

acceleration equal to 1G in magnitude is 25 mV for a Wheatstone bridge excitation of

10V. The thick and narrow hinge structure allows displacement within the plane of

Acceleration

Outer frame

Base

Mass

Hinge

Bondpads

{110} plane

Lid

Boron doped

piezoresistor

Figure 4.15 Illustration of a piezoresistive accelerometer from Endevco Corp., fabricated using

anisotropic etching in a {110} wafer. The middle core contains the inertial mass suspended from a

hinge. Two piezoresistive sense elements measure the deflection of the mass. The axis of sensitivity

is in the plane of the middle core. The outer frame acts as a stop mechanism to prevent excessive

accelerations from damaging the part. (After: [19].)