Page 122 - An Introduction to Microelectromechanical Systems Engineering

P. 122

Sensors and Analysis Systems 101

Capacitive Surface Micromachined Accelerometer

Surface micromachining emerged in the late 1980s as a perceived low-cost alterna-

tive for accelerometers aimed primarily at automotive applications. Both Robert

Bosch GmbH of Stuttgart, Germany, and Analog Devices, Inc., of Norwood, Mas-

sachusetts, offer surface micromachined accelerometers, but it is the latter company

that benefited from wide publicity to their ADXL product family [21]. The Bosch

sensor [22] is incorporated in the Mercedes Benz family of luxury automobiles. The

ADXL parts are used on board Ford, General Motors, and other vehicles, as well as

inside joysticks for computer games. The surface micromachining fabrication

sequence, illustrated in Chapter 3, is fundamentally similar to both sensors, though

the Bosch device uses a thicker (10-µm) polysilicon structural element.

Unlike most bulk-micromachined parts, surface-micromachined accelerometers

incorporate a suspended comb-like structure whose primary axis of sensitivity lies

in the plane of the die. This is often referred to as an x-axis (or y-axis) type of device,

as opposed to z-axis sensors where the sense axis is orthogonal to the plane of the

die. However, due to the relative thinness of their structural elements, surface

micromachined accelerometers suffer from sensitivity to accelerations out of the

plane of the die (z-axis). Shocks along this direction can cause catastrophic failures.

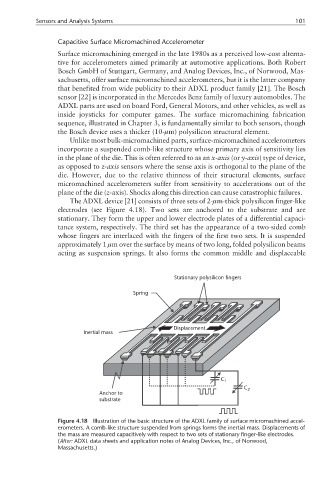

The ADXL device [21] consists of three sets of 2-µm-thick polysilicon finger-like

electrodes (see Figure 4.18). Two sets are anchored to the substrate and are

stationary. They form the upper and lower electrode plates of a differential capaci-

tance system, respectively. The third set has the appearance of a two-sided comb

whose fingers are interlaced with the fingers of the first two sets. It is suspended

approximately 1 µm over the surface by means of two long, folded polysilicon beams

acting as suspension springs. It also forms the common middle and displaceable

Stationary polysilicon fingers

Spring

Displacement

Inertial mass

C 1

C 2

Anchor to

substrate

Figure 4.18 Illustration of the basic structure of the ADXL family of surface micromachined accel-

erometers. A comb-like structure suspended from springs forms the inertial mass. Displacements of

the mass are measured capacitively with respect to two sets of stationary finger-like electrodes.

(After: ADXL data sheets and application notes of Analog Devices, Inc., of Norwood,

Massachusetts.)