Page 121 - An Introduction to Microelectromechanical Systems Engineering

P. 121

100 MEM Structures and Systems in Industrial and Automotive Applications

Silicon

Glass

Metal contact to

top wafer

Air damping vias Silicon

Inertial mass

Metal contact to

middle wafer

Metal electrode Contact to

substrate

Metal contact to

lower wafer

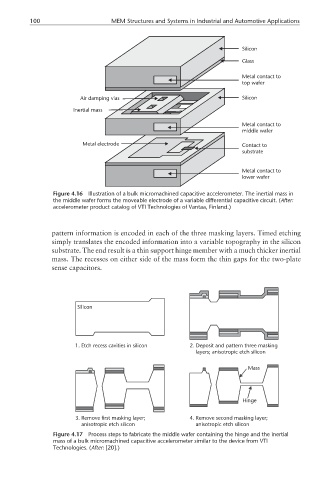

Figure 4.16 Illustration of a bulk micromachined capacitive accelerometer. The inertial mass in

the middle wafer forms the moveable electrode of a variable differential capacitive circuit. (After:

accelerometer product catalog of VTI Technologies of Vantaa, Finland.)

pattern information is encoded in each of the three masking layers. Timed etching

simply translates the encoded information into a variable topography in the silicon

substrate. The end result is a thin support hinge member with a much thicker inertial

mass. The recesses on either side of the mass form the thin gaps for the two-plate

sense capacitors.

Silicon

1. Etch recess cavities in silicon 2. Deposit and pattern three masking

layers; anisotropic etch silicon

Mass

Hinge

3. Remove first masking layer; 4. Remove second masking layer;

anisotropic etch silicon anisotropic etch silicon

Figure 4.17 Process steps to fabricate the middle wafer containing the hinge and the inertial

mass of a bulk micromachined capacitive accelerometer similar to the device from VTI

Technologies. (After: [20].)