Page 109 - An Introduction to Microelectromechanical Systems Engineering

P. 109

88 MEM Structures and Systems in Industrial and Automotive Applications

surface where through-holes are desired. Metal is then electroplated everywhere in

the mandrel that is not protected by the photoresist. Finally, the plated metal-foil

structure is peeled off of the mandrel and the resist is stripped. A later section in this

chapter describes the inkjet head in greater detail.

Hinge Mechanisms

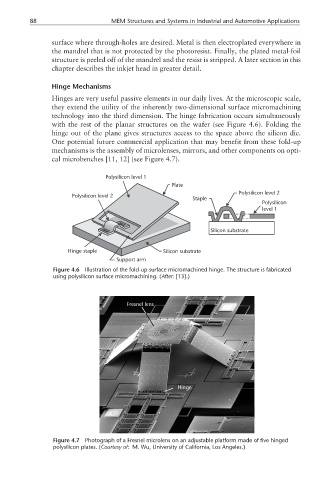

Hinges are very useful passive elements in our daily lives. At the microscopic scale,

they extend the utility of the inherently two-dimensional surface micromachining

technology into the third dimension. The hinge fabrication occurs simultaneously

with the rest of the planar structures on the wafer (see Figure 4.6). Folding the

hinge out of the plane gives structures access to the space above the silicon die.

One potential future commercial application that may benefit from these fold-up

mechanisms is the assembly of microlenses, mirrors, and other components on opti-

cal microbenches [11, 12] (see Figure 4.7).

Polysilicon level 1

Plate

Polysilicon level 2

Polysilicon level 2

Staple

Polysilicon

level 1

Silicon substrate

Hinge staple Silicon substrate

Support arm

Figure 4.6 Illustration of the fold-up surface micromachined hinge. The structure is fabricated

using polysilicon surface micromachining. (After: [13].)

Fresnel lens

Hinge

Figure 4.7 Photograph of a Fresnel microlens on an adjustable platform made of five hinged

polysilicon plates. (Courtesy of: M. Wu, University of California, Los Angeles.)