Page 133 - An Introduction to Microelectromechanical Systems Engineering

P. 133

112 MEM Structures and Systems in Industrial and Automotive Applications

fusion bonding brings these substrates together such that the cavities are facing each

other. The cavity depth determines the separation between the two tines. An etch step

in TMAH removes the silicon on the front side and stops on the buried silicon diox-

ide layer which is subsequently removed in hydrofluoric acid. The following steps

define the piezoelectric and piezoresistive elements on the silicon surface. Diffused

piezoresistors are formed using ion implantation and diffusion. Piezoelectric alumi-

num nitride is then deposited by sputtering aluminum in a controlled nitrogen and

argon atmosphere. This layer is lithographically patterned and etched in the shape of

the excitation plate over the tine. Aluminum is then sputtered and patterned to form

electrical interconnects and bond pads. Finally, a TMAH etch step from the back side

removes the silicon from underneath the tines. The buried silicon dioxide layer acts as

an etch stop. An anisotropic plasma etch from the front side releases the tines.

The measured frequency of the primary, flexural mode (excitation

mode) was 32.2 kHz, whereas the torsional secondary mode (sense mode) was

245 Hz lower. Typical of tuning forks, the frequencies exhibited a temperature

dependence. For this particular technology, the temperature coefficient of fre-

quency is –0.85 Hz/ºC.

Angular-Rate Sensor from Robert Bosch

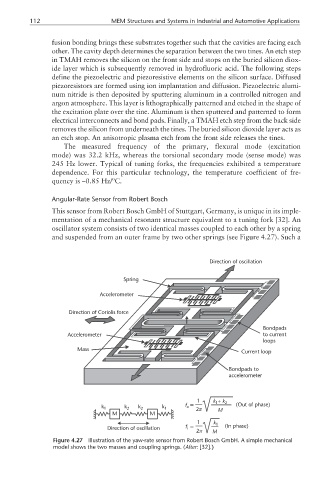

This sensor from Robert Bosch GmbH of Stuttgart, Germany, is unique in its imple-

mentation of a mechanical resonant structure equivalent to a tuning fork [32]. An

oscillator system consists of two identical masses coupled to each other by a spring

and suspended from an outer frame by two other springs (see Figure 4.27). Such a

Direction of oscillation

Spring

Accelerometer

Direction of Coriolis force

Bondpads

Accelerometer to current

loops

Mass

Current loop

Bondpads to

accelerometer

1 k + k 2

1

k 1 k 2 k 2 k 1 f o = 2π (Out of phase)

M M M

1 k 1

Direction of oscillation f = (In phase)

i

2π M

Figure 4.27 Illustration of the yaw-rate sensor from Robert Bosch GmbH. A simple mechanical

model shows the two masses and coupling springs. (After: [32].)