Page 136 - An Introduction to Microelectromechanical Systems Engineering

P. 136

Sensors and Analysis Systems 115

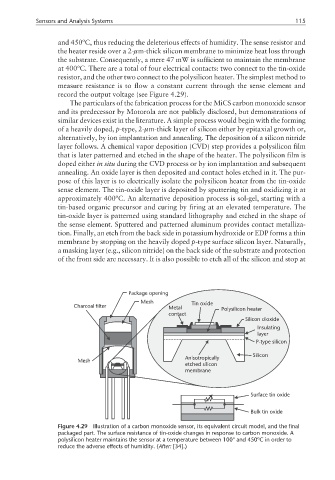

and 450ºC, thus reducing the deleterious effects of humidity. The sense resistor and

the heater reside over a 2-µm-thick silicon membrane to minimize heat loss through

the substrate. Consequently, a mere 47 mW is sufficient to maintain the membrane

at 400ºC. There are a total of four electrical contacts: two connect to the tin-oxide

resistor, and the other two connect to the polysilicon heater. The simplest method to

measure resistance is to flow a constant current through the sense element and

record the output voltage (see Figure 4.29).

The particulars of the fabrication process for the MiCS carbon monoxide sensor

and its predecessor by Motorola are not publicly disclosed, but demonstrations of

similar devices exist in the literature. A simple process would begin with the forming

of a heavily doped, p-type, 2-µm-thick layer of silicon either by epitaxial growth or,

alternatively, by ion implantation and annealing. The deposition of a silicon nitride

layer follows. A chemical vapor deposition (CVD) step provides a polysilicon film

that is later patterned and etched in the shape of the heater. The polysilicon film is

doped either in situ during the CVD process or by ion implantation and subsequent

annealing. An oxide layer is then deposited and contact holes etched in it. The pur-

pose of this layer is to electrically isolate the polysilicon heater from the tin-oxide

sense element. The tin-oxide layer is deposited by sputtering tin and oxidizing it at

approximately 400ºC. An alternative deposition process is sol-gel, starting with a

tin-based organic precursor and curing by firing at an elevated temperature. The

tin-oxide layer is patterned using standard lithography and etched in the shape of

the sense element. Sputtered and patterned aluminum provides contact metalliza-

tion. Finally, an etch from the back side in potassium hydroxide or EDP forms a thin

membrane by stopping on the heavily doped p-type surface silicon layer. Naturally,

a masking layer (e.g., silicon nitride) on the back side of the substrate and protection

of the front side are necessary. It is also possible to etch all of the silicon and stop at

Package opening

Mesh Tin oxide

Charcoal filter Metal Polysilicon heater

contact

Silicon dioxide

Insulating

layer

P-type silicon

Silicon

Anisotropically

Mesh

etched silicon

membrane

Surface tin oxide

Bulk tin oxide

Figure 4.29 Illustration of a carbon monoxide sensor, its equivalent circuit model, and the final

packaged part. The surface resistance of tin-oxide changes in response to carbon monoxide. A

polysilicon heater maintains the sensor at a temperature between 100° and 450ºC in order to

reduce the adverse effects of humidity. (After: [34].)