Page 141 - An Introduction to Microelectromechanical Systems Engineering

P. 141

120 MEM Structures and Systems in Industrial and Automotive Applications

Micromachined Valve from Redwood Microsystems

Early development of this valve took place in the mid 1980s at Stanford University

[44]. Redwood Microsystems was founded shortly thereafter with the objective of

commercializing the valve. The actuation mechanism of either normally open or

3

normally closed valves depends on the electrical heating of a control liquid sealed

inside a cavity. When the temperature of the liquid rises, its pressure increases, thus

exerting a force on a thin diaphragm wall and flexing it outward.

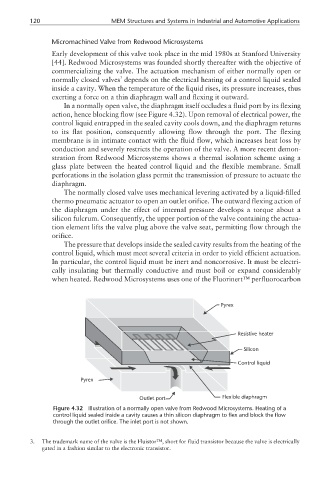

In a normally open valve, the diaphragm itself occludes a fluid port by its flexing

action, hence blocking flow (see Figure 4.32). Upon removal of electrical power, the

control liquid entrapped in the sealed cavity cools down, and the diaphragm returns

to its flat position, consequently allowing flow through the port. The flexing

membrane is in intimate contact with the fluid flow, which increases heat loss by

conduction and severely restricts the operation of the valve. A more recent demon-

stration from Redwood Microsystems shows a thermal isolation scheme using a

glass plate between the heated control liquid and the flexible membrane. Small

perforations in the isolation glass permit the transmission of pressure to actuate the

diaphragm.

The normally closed valve uses mechanical levering activated by a liquid-filled

thermo pneumatic actuator to open an outlet orifice. The outward flexing action of

the diaphragm under the effect of internal pressure develops a torque about a

silicon fulcrum. Consequently, the upper portion of the valve containing the actua-

tion element lifts the valve plug above the valve seat, permitting flow through the

orifice.

The pressure that develops inside the sealed cavity results from the heating of the

control liquid, which must meet several criteria in order to yield efficient actuation.

In particular, the control liquid must be inert and noncorrosive. It must be electri-

cally insulating but thermally conductive and must boil or expand considerably

when heated. Redwood Microsystems uses one of the Fluorinert™ perfluorocarbon

Pyrex

Resistive heater

Silicon

Control liquid

Pyrex

Outlet port Flexible diaphragm

Figure 4.32 Illustration of a normally open valve from Redwood Microsystems. Heating of a

control liquid sealed inside a cavity causes a thin silicon diaphragm to flex and block the flow

through the outlet orifice. The inlet port is not shown.

3. The trademark name of the valve is the Fluistor™, short for fluid transistor because the valve is electrically

gated in a fashion similar to the electronic transistor.