Page 143 - An Introduction to Microelectromechanical Systems Engineering

P. 143

122 MEM Structures and Systems in Industrial and Automotive Applications

diaphragm in the middle of the silicon wafer. The top glass wafer is processed

separately to form a sputtered thin-film metal heater. Ultrasonic drilling opens a fill

hole through the top Pyrex glass substrate, as well as the inlet and outlet ports in the

lower Pyrex glass substrate. Both glass substrates are sequentially bonded to the sili-

con wafer using anodic bonding. In the final step, the Fluorinert liquid fills the cav-

ity. Special silicone compounds dispensed over the fill hole permanently seal the

Fluorinert inside the cavity.

Micromachined Valve from TiNi Alloy Company

TiNi Alloy Company of San Leandro, California, is another small company with the

objective of commercializing micromachined valves. Its design approach, however, is

very different than that of Redwood Microsystems. The actuation mechanism relies

on titanium-nickel (TiNi) [45], a shape-memory alloy—hence the name of the com-

pany. The rationale is that shape-memory alloys are very efficient actuators and can

produce a large volumetric energy density, approximately five to 10 times higher

than competing actuation methods. It is, however, the integration of TiNi processing

with mainstream silicon manufacturing that remains an important hurdle.

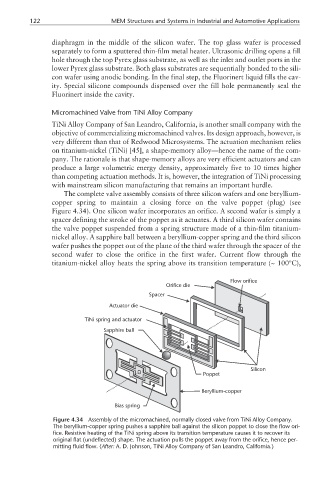

The complete valve assembly consists of three silicon wafers and one beryllium-

copper spring to maintain a closing force on the valve poppet (plug) (see

Figure 4.34). One silicon wafer incorporates an orifice. A second wafer is simply a

spacer defining the stroke of the poppet as it actuates. A third silicon wafer contains

the valve poppet suspended from a spring structure made of a thin-film titanium-

nickel alloy. A sapphire ball between a beryllium-copper spring and the third silicon

wafer pushes the poppet out of the plane of the third wafer through the spacer of the

second wafer to close the orifice in the first wafer. Current flow through the

titanium-nickel alloy heats the spring above its transition temperature (~ 100ºC),

Flow orifice

Orifice die

Spacer

Actuator die

TiNi spring and actuator

Sapphire ball

Silicon

Poppet

Beryllium-copper

Bias spring

Figure 4.34 Assembly of the micromachined, normally closed valve from TiNi Alloy Company.

The beryllium-copper spring pushes a sapphire ball against the silicon poppet to close the flow ori-

fice. Resistive heating of the TiNi spring above its transition temperature causes it to recover its

original flat (undeflected) shape. The actuation pulls the poppet away from the orifice, hence per-

mitting fluid flow. (After: A. D. Johnson, TiNi Alloy Company of San Leandro, California.)