Page 139 - An Introduction to Microelectromechanical Systems Engineering

P. 139

118 MEM Structures and Systems in Industrial and Automotive Applications

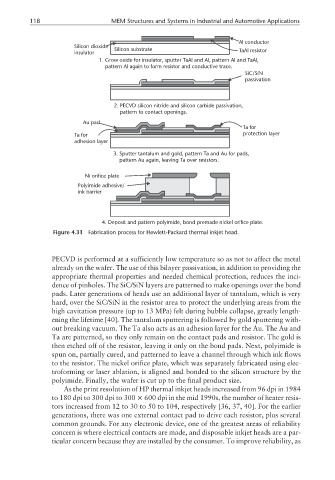

Al conductor

Silicon dioxide

Silicon substrate TaAl resistor

insulator

1. Grow oxide for insulator, sputter TaAl and Al, pattern Al and TaAl,

pattern Al again to form resistor and conductive trace.

SiC/SiN

passivation

2. PECVD silicon nitride and silicon carbide passivation,

pattern to contact openings.

Au pad

Ta for

Ta for protection layer

adhesion layer

3. Sputter tantalum and gold, pattern Ta and Au for pads,

pattern Au again, leaving Ta over resistors.

Ni orifice plate

Polyimide adhesive/

ink barrier

4. Deposit and pattern polyimide, bond premade nickel orifice plate.

Figure 4.31 Fabrication process for Hewlett-Packard thermal inkjet head.

PECVD is performed at a sufficiently low temperature so as not to affect the metal

already on the wafer. The use of this bilayer passivation, in addition to providing the

appropriate thermal properties and needed chemical protection, reduces the inci-

dence of pinholes. The SiC/SiN layers are patterned to make openings over the bond

pads. Later generations of heads use an additional layer of tantalum, which is very

hard, over the SiC/SiN in the resistor area to protect the underlying areas from the

high cavitation pressure (up to 13 MPa) felt during bubble collapse, greatly length-

ening the lifetime [40]. The tantalum sputtering is followed by gold sputtering with-

out breaking vacuum. The Ta also acts as an adhesion layer for the Au. The Au and

Ta are patterned, so they only remain on the contact pads and resistor. The gold is

then etched off of the resistor, leaving it only on the bond pads. Next, polyimide is

spun on, partially cured, and patterned to leave a channel through which ink flows

to the resistor. The nickel orifice plate, which was separately fabricated using elec-

troforming or laser ablation, is aligned and bonded to the silicon structure by the

polyimide. Finally, the wafer is cut up to the final product size.

As the print resolution of HP thermal inkjet heads increased from 96 dpi in 1984

to 180 dpi to 300 dpi to 300 × 600 dpi in the mid 1990s, the number of heater resis-

tors increased from 12 to 30 to 50 to 104, respectively [36, 37, 40]. For the earlier

generations, there was one external contact pad to drive each resistor, plus several

common grounds. For any electronic device, one of the greatest areas of reliability

concern is where electrical contacts are made, and disposable inkjet heads are a par-

ticular concern because they are installed by the consumer. To improve reliability, as