Page 148 - An Introduction to Microelectromechanical Systems Engineering

P. 148

Actuators and Actuated Microsystems 127

development activities appears to be. An application for micropumps is likely to

be in the automated handling of fluids for chemical analysis and drug delivery

systems.

Stand-alone micropump units face significant competition from traditional

solenoid or stepper-motor-actuated pumps. For instance, The Lee Company of

Westbrook, Connecticut, manufactures a family of pumps measuring approxi-

mately 51 mm × 12.7 mm × 19 mm (2 in × 0.5 in × 0.75 in) and weighing, fully

packaged, a mere 50g (1.8 oz). They can dispense up to 6 ml/min with a power

consumption of 2W from a 12-V dc supply. But micromachined pumps can have a

significant advantage if they can be readily integrated along with other fluid-

handling components, such as valves, into one completely automated miniature

system. The following demonstration from the Fraunhofer Institute for Solid State

Technology of Munich, Germany [48], illustrates one successful effort at making a

bidirectional micropump with reasonable flow rates.

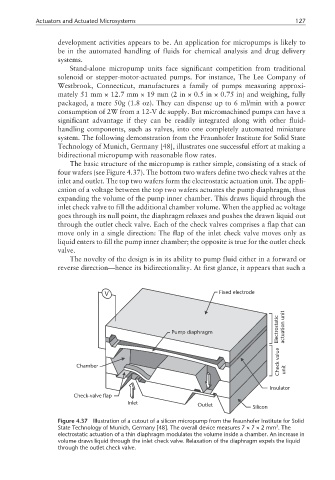

The basic structure of the micropump is rather simple, consisting of a stack of

four wafers (see Figure 4.37). The bottom two wafers define two check valves at the

inlet and outlet. The top two wafers form the electrostatic actuation unit. The appli-

cation of a voltage between the top two wafers actuates the pump diaphragm, thus

expanding the volume of the pump inner chamber. This draws liquid through the

inlet check valve to fill the additional chamber volume. When the applied ac voltage

goes through its null point, the diaphragm relaxes and pushes the drawn liquid out

through the outlet check valve. Each of the check valves comprises a flap that can

move only in a single direction: The flap of the inlet check valve moves only as

liquid enters to fill the pump inner chamber; the opposite is true for the outlet check

valve.

The novelty of the design is in its ability to pump fluid either in a forward or

reverse direction—hence its bidirectionality. At first glance, it appears that such a

V Fixed electrode

Electrostatic unit

Pump diaphragm actuation

value

Check unit

Chamber

Insulator

Check-valve flap

Inlet Outlet Silicon

Figure 4.37 Illustration of a cutout of a silicon micropump from the Fraunhofer Institute for Solid

3

State Technology of Munich, Germany [48]. The overall device measures7×7×2mm . The

electrostatic actuation of a thin diaphragm modulates the volume inside a chamber. An increase in

volume draws liquid through the inlet check valve. Relaxation of the diaphragm expels the liquid

through the outlet check valve.