Page 160 - An Introduction to Microelectromechanical Systems Engineering

P. 160

Imaging and Displays 139

silicon along edge scribe lines to a depth that allows breaking the individual dice

apart at a later stage. An oxygen-plasma etch step removes both sacrificial layers

and releases the micromirrors. A special passivation step deposits a thin, antistiction

layer to prevent any adhesion between the yoke and the landing pads. Finally, a sin-

gulation process breaks apart and separates the individual dice. The packaging of

the DMD is discussed in Chapter 8.

Reliability is the sine qua non of the commercial success of DMD technology.

The designs described here are the result of extensive efforts at Texas Instruments

aimed at understanding the long-term operation of the pixels as well as their fail-

ure modes. The DMD micromirrors are sufficiently robust to withstand normal

environmental and handling conditions, including 1,500G mechanical shocks,

because the weight of the micromirrors is insignificant. The major failure and

malfunction mechanisms are surface contamination and hinge memory. The latter

is the result of metal creep in the hinge material and causes the mirror to exhibit a

residual tilt in the absence of actuation voltages. The reliability of the DMD is

further discussed in Chapter 8.

Grating Light Valve™ Display

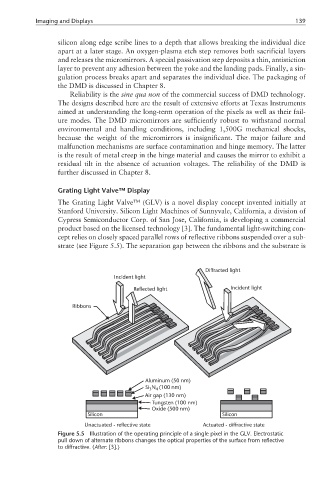

The Grating Light Valve™ (GLV) is a novel display concept invented initially at

Stanford University. Silicon Light Machines of Sunnyvale, California, a division of

Cypress Semiconductor Corp. of San Jose, California, is developing a commercial

product based on the licensed technology [3]. The fundamental light-switching con-

cept relies on closely spaced parallel rows of reflective ribbons suspended over a sub-

strate (see Figure 5.5). The separation gap between the ribbons and the substrate is

Diffracted light

Incident light

Reflected light Incident light

Ribbons

Aluminum (50 nm)

Si N (100 nm)

4

3

Air gap (130 nm)

Tungsten (100 nm)

Oxide (500 nm)

Silicon Silicon

Unactuated - reflective state Actuated - diffractive state

Figure 5.5 Illustration of the operating principle of a single pixel in the GLV. Electrostatic

pull down of alternate ribbons changes the optical properties of the surface from reflective

to diffractive. (After: [3].)