Page 87 - An Introduction to Microelectromechanical Systems Engineering

P. 87

66 Processes for Micromachining

pattern on the underlying substrate. Drying evaporates the solvent. Firing burns off

the organic binder and sinters the remaining metal or ceramic into a solid, resulting

in a known amount of shrinkage. Metal lines with 125-µm lines and spaces are made

in the production of ceramic packaging (discussed further in Chapter 8) [30], with

30-µm features demonstrated [31]. Film thicknesses after firing range from roughly

10 to 200 µm. Multiple layers of different materials can be stacked.

Microcontact Printing/Soft Lithography

Microcontact printing, a microscale form of ink printing also called soft lithogra-

phy, has been studied by several research groups [32, 33]. It enables low-cost

production of submicrometer patterns and has been studied as an alternative

to conventional photolithography, but is not presently a product fabrication

method.

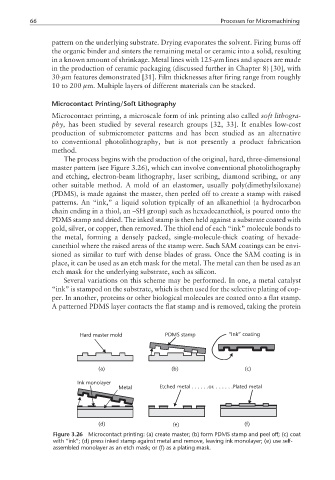

The process begins with the production of the original, hard, three-dimensional

master pattern (see Figure 3.26), which can involve conventional photolithography

and etching, electron-beam lithography, laser scribing, diamond scribing, or any

other suitable method. A mold of an elastomer, usually poly(dimethylsiloxane)

(PDMS), is made against the master, then peeled off to create a stamp with raised

patterns. An “ink,” a liquid solution typically of an alkanethiol (a hydrocarbon

chain ending in a thiol, an –SH group) such as hexadecanethiol, is poured onto the

PDMS stamp and dried. The inked stamp is then held against a substrate coated with

gold, silver, or copper, then removed. The thiol end of each “ink” molecule bonds to

the metal, forming a densely packed, single-molecule-thick coating of hexade-

canethiol where the raised areas of the stamp were. Such SAM coatings can be envi-

sioned as similar to turf with dense blades of grass. Once the SAM coating is in

place, it can be used as an etch mask for the metal. The metal can then be used as an

etch mask for the underlying substrate, such as silicon.

Several variations on this scheme may be performed. In one, a metal catalyst

“ink” is stamped on the substrate, which is then used for the selective plating of cop-

per. In another, proteins or other biological molecules are coated onto a flat stamp.

A patterned PDMS layer contacts the flat stamp and is removed, taking the protein

Hard master mold PDMS stamp “Ink” coating

(a) (b) (c)

Ink monolayer

Metal Etched metal......or...... .Plated metal

(d) (e) (f)

Figure 3.26 Microcontact printing: (a) create master; (b) form PDMS stamp and peel off; (c) coat

with “ink”; (d) press inked stamp against metal and remove, leaving ink monolayer; (e) use self-

assembled monolayer as an etch mask; or (f) as a plating mask.