Page 91 - An Introduction to Microelectromechanical Systems Engineering

P. 91

70 Processes for Micromachining

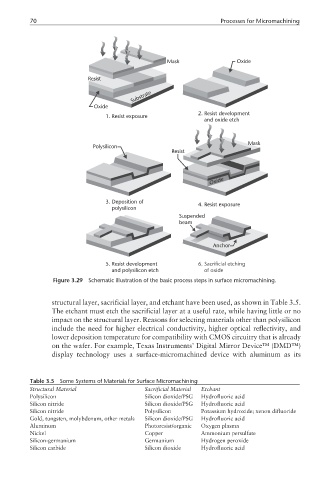

Mask Oxide

Resist

Substrate

Oxide

2. Resist development

1. Resist exposure

and oxide etch

Mask

Polysilicon

Resist

Oxide

3. Deposition of 4. Resist exposure

polysilicon

Suspended

beam

Anchor

5. Resist development 6. Sacrificial etching

and polysilicon etch of oxide

Figure 3.29 Schematic illustration of the basic process steps in surface micromachining.

structural layer, sacrificial layer, and etchant have been used, as shown in Table 3.5.

The etchant must etch the sacrificial layer at a useful rate, while having little or no

impact on the structural layer. Reasons for selecting materials other than polysilicon

include the need for higher electrical conductivity, higher optical reflectivity, and

lower deposition temperature for compatibility with CMOS circuitry that is already

on the wafer. For example, Texas Instruments’ Digital Mirror Device™ (DMD™)

display technology uses a surface-micromachined device with aluminum as its

Table 3.5 Some Systems of Materials for Surface Micromachining

Structural Material Sacrificial Material Etchant

Polysilicon Silicon dioxide/PSG Hydrofluoric acid

Silicon nitride Silicon dioxide/PSG Hydrofluoric acid

Silicon nitride Polysilicon Potassium hydroxide; xenon difluoride

Gold, tungsten, molybdenum, other metals Silicon dioxide/PSG Hydrofluoric acid

Aluminum Photoresist/organic Oxygen plasma

Nickel Copper Ammonium persulfate

Silicon-germanium Germanium Hydrogen peroxide

Silicon carbide Silicon dioxide Hydrofluoric acid